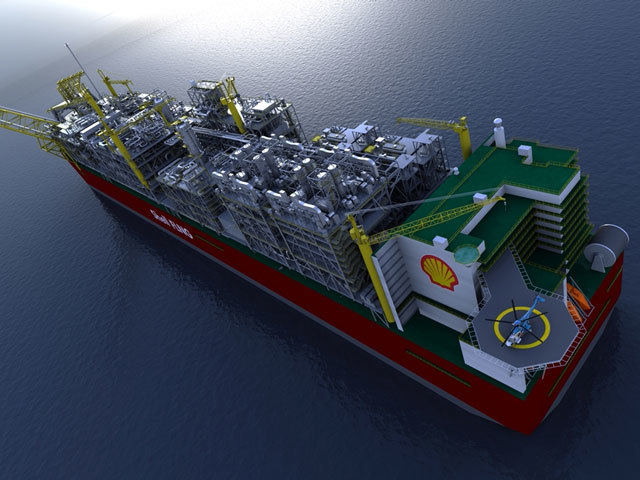

GE Oil & Gas today confirmed it had started production on four high pressure, high temperature dynamic flexible risers destined for Shell’s Prelude, the world’s largest offshore floating facility.

The firm is building them to survive a 1-in-10,000-year cyclonic event, according to the contract spec.

GE will complete the work at its facility in Newcastle, UK, where it has invested more than $21million to expand its production carousel capacity to accommodate the giant kit. They must also be able to withstand high pressures, high operating temperatures, the potential for cold shut-downs and rapid depressurisation.

Andrew Atkinson, commercial director, Asia-Pacific and India at GE Oil & Gas, said: “Despite the industry downturn continuing to affect the LNG market, long-term we believe FLNG has the potential to evolve into a promising segment, particularly in the Asia Pacific region, where there are areas of high energy demand and the presence of large-scale offshore gas fields. Notwithstanding that, investment in HP/HT technologies should be viewed as critical for both operators and the supply chain looking at exploiting ever-more challenging environments. I am proud of the skills and expertise of our team, who have demonstrated the commitment we make to our customers to develop industry-leading, future-oriented technology solutions to meet their needs.”

Once manufactured, the flexible risers will be packaged onto purpose built large-diameter reels and transported more than 11,000kms between Newcastle and South East Asia where they will be installed.

GE’s project teams for Prelude are based between Perth, Australia, and Newcastle for the subsea equipment scope and Florence, Italy for the manufacture and supply of two steam turbine-driven compressors, vital elements for the liquefaction process.