A device designed to help kill blowouts has been given an upgrade.

The Relief Well Injection Spool (RWIS) increases the flow capacity to a single relief well.

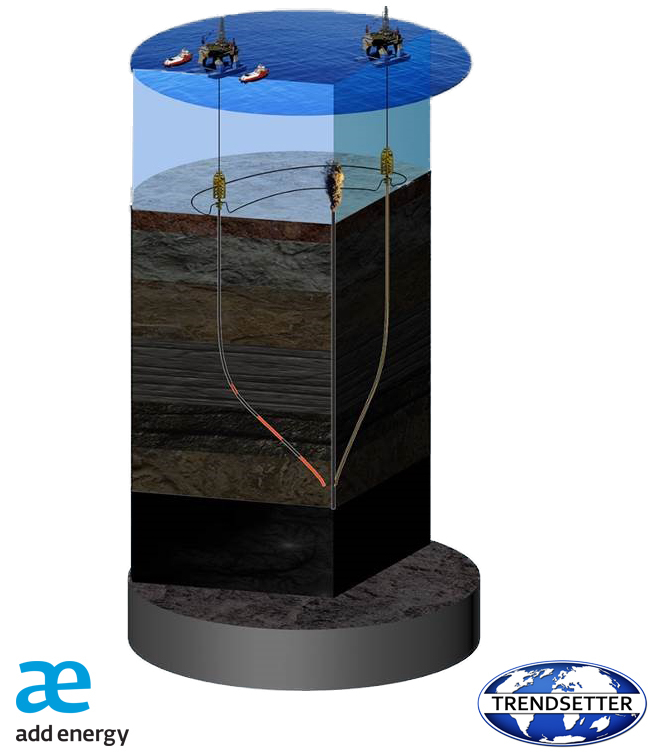

Relief wells are drilled when a well blows in order to reduce the pressure and inject kill fluids like heavy mud.

The RWIS was designed and made in a partnership between consultancy Add Energy and subsea specialists Trendsetter Engineering.

Increasing the flow of one single relief makes it safer and less challenging than drilling multiple relief wells during a well blowout.

The RWIS is placed between the relief wellhead and the blowout preventor to allow multiple pumping vessels to inject the kill fluid into the relief well in a more cost and time efficient manner.

Now the two firms have unveiled the RWIS Lite to simplify installation.

The Lite is a flow spool without controls, allowing operators to install BOP’s above the spool, greatly reducing the complexity of hooking up kill vessels to the system.

This enhancement excludes gate valves, accumulators, ROV panels and a BOP, reducing the complexity of the subsea hardware configuration.

“When the RWIS Lite is used alongside an RWIS, it requires one less drill ship and utilizes the existing BOP emergency disconnect system for maximum efficiency,” said Morten Haug Emilsen, managing director for Add Energy.

“The RWIS was a first for the industry and now the RWIS Lite represents an evolution of the technology.”

Recommended for you