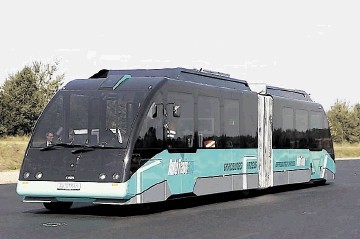

THEY call it a tram but most of you would think of it as a bendi-bus as it has rubber wheels, even though the early prototypes are double-ended.

It doesn’t run on tracks, rather it follows white lines on the street.

And it is free of smelly exhaust emissions because tomorrow’s city transport employs electricity, hydrogen or a combination of various regenerative drives.

So far, more than £30million of public money has been pumped into the AutoTram experiment, with two vehicles built and extensively tested.

The first designs of the AutoTram were built a couple of years ago and incorporate both high-efficiency batteries and innovative super-capacitors to “store” electricity.

Unlike cars, that apparently park an average of 23 hours a day, buses and trains are on the road the whole day so there isn’t much time to charge batteries.

Researchers behind the project suggest that a potential solution is fast-charging stations at bus stops in combination with dual-storage units in the vehicle itself.

The tram taps the quantity of energy it needs to make it to the next stop or the stop after that in only 20-30 seconds During this time passengers are getting in and out.

Dr Ulrich Potthoff of the Fraunhoffer Institute describes the principles behind super capacitors: “Batteries take a certain amount of time to charge.

“You can compare that with a large bathtub and a small supply.

“On the other hand, capacitors absorb the charge very quickly like a small bathtub and a large supply. Unfortunately, they can only store a small amount of energy.

“This is why engineers are now working at linking the battery system and capacitors to achieve optimal efficiency.

“We are coming up with dual storage units and also testing combinations with other storage models and fuel cells.”

The research work continues and the research team is now working with a bus manufacturer to come up with a test a vehicle that actually reminds you more of a run-of-the-mill bus.