By decarbonising industrial and domestic heating, I am convinced that hydrogen has a significant role towards achieving net zero. However, the role of hydrogen in the passenger car sector is much less clear. I find it difficult to see how a hydrogen powered fuel cell electric vehicle (FCEV) can compete with a battery electric vehicle (BEV). That conclusion was reinforced by two recent reports from BloombergNEF and Volkswagen.

BloombergNEF, Hydrogen Economy Outlook report, March 30, 2020 concluded the following “Hydrogen can play a valuable role decarbonizing long-haul, heavy-payload trucks. These could be cheaper to run using hydrogen fuel cells than diesel engines by 2031. But the bulk of the car, bus and light-truck market looks set to adopt battery electric drive trains, which are a cheaper solution than fuel cells.”

Volkswagen, however, did not use high FCEV costs to support the development of the BEV – they used a fundamental energy balance to demonstrate the substantial energy efficiency benefit of a BEV over an FCEV. The BEV is twice as efficient. Volkswagen are unequivocal in their report where the following statement is made – “The conclusion is clear: in the case of the passenger car, everything speaks in favor of the battery and practically nothing speaks in favor of hydrogen. “

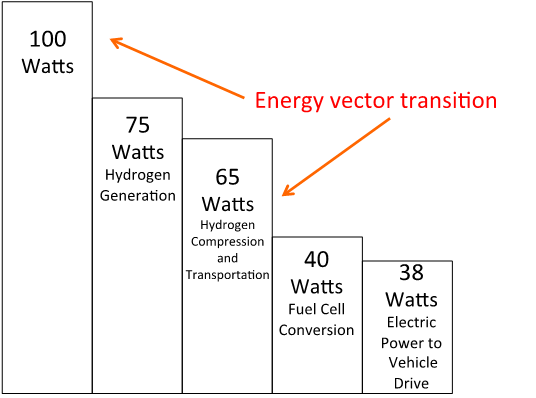

FCEVs are based upon a number of energy vector transitions – wire to gas to wire – whereas the BEV has no transition, it is wire throughout. At each vector transition there will be a substantial loss of efficiency and therein lies the issue with the FCEV.

Let’s take 100 Watts of electricity produced by a renewable source. For the FCEV that energy is used to produce hydrogen, possibly using electrolysis, a process that is around 75% energy efficient (steam methane reforming with CCS has a comparable efficiency). The hydrogen produced has to be compressed, chilled and transported to the hydrogen station, a process that is around 90% efficient. The hydrogen is then converted to electricity in the car fuel cell, a process that is around 60% efficient. Finally the electricity is used in a motor to provide vehicle drive, a process that is around 95% efficient. The compounding energy inefficiencies mean that only 38% of the original energy production is used to move the car. This is illustrated in the following figure 1.

Figure 1 – FCEV energy steps

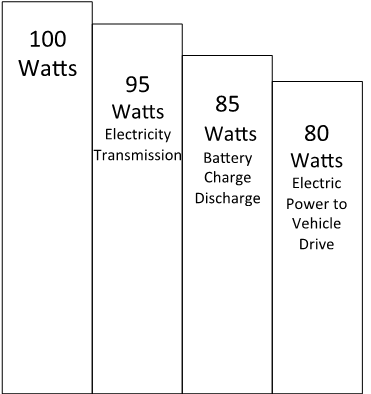

The BEV steps have no energy vector transition – it is all electric (wire). 100 Watts of energy is transmitted to a battery with 5% losses. Charging and discharging a Lithium-ion battery results in around 10% losses and the electricity used in a motor to provide vehicle drive has a 5% loss. These steps are illustrated in figure 2.

Figure 2 – BEV energy steps

As is evident from the figures, the FCEV requires double the energy of the BEV. This is confirmed by BMW where on reviewing the FCEV it is stated “The overall efficiency in the power to vehicle drive energy chain is therefore only half the level of a BEV.”

So why hydrogen for small vehicles? Currently the benefits are increased range and much reduced charge times. Not insignificant benefits, however, both these areas are the subject of much BEV research with charge times reducing and range increasing.

It is interesting to note that there are many reports of Mercedes halting the development of their small passenger car FCEV and will focus on large FCEV trucks in a joint venture with Volvo.

Tom Baxter is visiting professor of chemical engineering at Strathclyde University and a retired technical director at Genesis Oil and Gas Consultants

Recommended for you