Norway’s Statoil has notched up a subsea first by employing a remote-controlled machine and an underwater welding robot to install a new tie-in point on a live North Sea gas pipeline, without the hydrocarbons transport infrastructure being prepared in advance.

The semi-state oil company worked with subsea contracting major Technip to set this important new milestone and expects that this approach will save considerable cost.

It said that the hot-tap installation is the first to be carried out in connection with preparations for Asgard subsea gas compression in the Norwegian Sea, and thus also represents a milestone for the project.

The tie-in point was welded on to the Asgard B production flowline at a water depth of 265m.

After 10 days on the field, the hot-tap operation team on board Technip’s vessel Scandi Arctic was able to advise that the pioneering operation was successful.

“For a subsea engineer, this can be compared with landing on Mars,” said Kjell Edvard Apeland, project manager of the remote-controlled hot-tap development in Statoil and head of the operation in the Asgard field.

The operation comprised a robot welding a T-piece on to the pipe while gas continued to flow through it, after which a remote-controlled drilling machine drilled holes in the producing pipeline, with no effect on pressure and production.

“When the compressor module and the manifold for Asgard subsea compression are installed next year, we will connect the pipeline from these to the hot-tap tie-in point,” said Apeland.

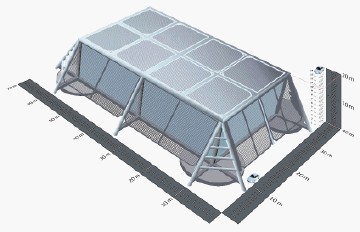

The Asgard subsea compression project should be completed in 2015 and rank as the first of its kind in the world. Compressors will be installed on the seabed, instead of on a platform.

This is designed to improve recovery from the Mikkel and Midgard reservoirs by around 280million barrels oil equivalent. The kit will cover an area almost the size of a football pitch.

It represents a major step forward in Statoil’s ambition to create what it refers to as the subsea factory of the future.

Hot-tap technology is still a breakthrough, and an important factor in developing marginal fields as well as extending the lifetime of other fields. Shell performed a hot-tap on the UK sector Flags export pipeline.

This enabled the tie-in of the 20km Tampen link pipeline from the Norwegian sector as part of Statoil’s Statfjord Late Life Project. Subsea 7 played the linchpin contractor role.

The ability to connect anywhere on a pipeline, without stopping production, yields considerable flexibility and significant savings.

“Since we will be connecting a new compressor station on the seabed to an existing pipeline system on Asgard, it is very beneficial to use the hot-tap technology to avoid disrupting production,” said Torstein Vintersto, portfolio manager for subsea compression projects in Statoil.

“The savings are measured compared with what it would have cost to perform a similar operation, including shutting down production in the pipeline we were working on. This would also have taken much longer than the 10 days we spent . . . possibly as long as three months.”

Besides the Flags hot-tap, Statoil also had a remote-controlled hot-tap for the Ormen Lange field in the Norwegian Sea, but then the T-piece had already been installed on the gas pipeline in advance.