Edinburgh-based flow assurance consultancy and lab services company Hydrafact has kicked off a joint industry project to develop an online hydrate inhibition monitoring system called Online HydraCHEK.

Energy can report that industry support for the 18-month-long project was secured with assistance from the global technology facilitator, ITF.

Gas hydrates are ice-like crystalline complexes that can form from mixtures of water and gas under the high-pressure, low-temperature conditions that commonly occur in offshore pipelines.

They can cause serious and costly flow assurance problems. And as the industry continues to mature, with more developments in deeper waters, longer subsea tiebacks and higher water cuts, the risk of hydrate formation has become more of a problem.

Saeid Mazloum, flow assurance engineer at Hydrafact, points out that chemical inhibitors are commonly used to control gas hydrate formation and are normally injected upstream of pipelines.

The dosage required is based on the calculated or measured hydrate phase boundary, water-cut, worst case pressure and temperature conditions and the amount of inhibitor lost to non-aqueous phases.

According to Mazloum, in many cases, large safety margins are used to account for the uncertainty in these parameters during the design phase and minimise the risk from gas hydrates during production.

He warns, however, that the overall result tends to be excessive over inhibition for many systems, the consequences of which are unnecessarily high capital and operational expenditure.

HydraCHEK was developed to address the issue of hydrate inhibition monitoring and to enable safe and efficient production operations.

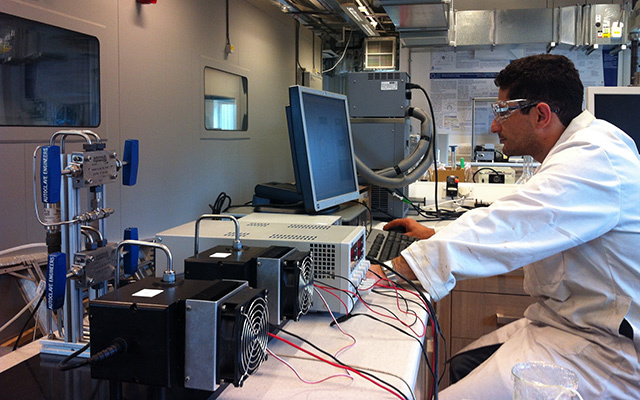

It is, at present, a lab-based device that measures the actual concentration of hydrate inhibitor and salt in a produced water sample taken from an oil and gas production system.

By taking the inhibitor and salt concentration data from HydraCHEK and combining it with the hydrocarbon composition and operating conditions, the hydrate stability zone and the hydrate safety margin can be determined for a system.

Inhibitor injection rates can then be adjusted to avoid hydrate blockage due to under-inhibition, or costly wastage as a result of over-inhibition and this new technology can apparently be used to rapidly and accurately monitor the effect of changing the dosage.

The system was initially developed by researchers at Heriot-Watt University’s Centre for Gas Hydrate Research, and spin-out company Hydrafact has an exclusive licence to commercialise the technology.

Mark Anju, senior technology analyst at ITF, says of progress to date:

“ITF was involved in helping Heriot-Watt secure support for development of the lab-based HydraCHEK system, so it is great to see continued industry interest in developing the technology.

“HydraCHEK is now being deployed worldwide on commercial field trials, operational rentals and equipment purchases, and a number of operators have expressed interest in the possibility of an online system.”

Hydrafact submitted a proposal to ITF in response to this demand and was successful in securing funding to develop an online system that will periodically sample produced water and report the results to the control room.

The advantage of near continuous data on hydrate inhibitor concentrations is that it will allow any problems to be identified and quickly dealt with.

It is also envisaged that hydrate inhibitor injection rates will be controlled automatically in response to the results from HydraCHEK, ensuring the optimal inhibitor dosage is achieved.

The potential for cost savings is significant.