There has never been so much pressure to wean the human species off its massive dependency on hydrocarbons; with the war in Ukraine and the staggeringly high temperatures recorded in the Arctic and Antarctic further forcing the Great Energy Transition into overdrive.

It’s not just about seeking new technologies, or novel permutations of exciting offerings, it is also about making what we are increasingly depending upon more efficient and sustainable in their own right.

WATER FROM THIN AIR

Among the most exciting perms currently being worked on is a solar-driven, novel hydrogel-based system that successfully grows spinach by using water drawn from the air while producing electricity.

It is unashamedly artisanal in nature.

Scientists at the King Abdullah University of Science and Technology (KAUST) in Saudi Arabia claim their design – now at proof-of-concept stage – offers a sustainable, low-cost strategy to improve food and water security for people living in dry-climate regions.

Reality is that a large slice of the human population has no or very little access to clean water or green power, with huge numbers of people forced to live in rural areas with arid or semi-arid climate.

According to Peng Wang, a professor of environmental science and engineering at KAUST, the design “makes water out of air using clean energy that would’ve been wasted and is suitable for decentralised, small-scale farms in remote places like deserts and oceanic islands”.

The system, known as WEC2P, comprises a solar panel placed atop a layer of hydrogel, which is mounted on top of a large metal box, the purpose of which is to condense and collect water.

The hydrogel comes from earlier research led by Wang at KAUST. The material can absorb water vapor from ambient air and release the water content when heated.

The researchers used the waste heat from solar panels when generating electricity to drive absorbed water out of the hydrogel. The metal box below collects the vapor and condenses the gas into water.

Alternatively, the hydrogel can be used to increase the efficiency of solar photovoltaic panels by as much as 9% by absorbing the heat and lowering the panels’ temperature.

An initial two-week trial utilising water collected from air to irrigate 60 water spinach seeds planted in a plastic plant-growing box was conducted.

Over the course of the experiment, the solar panel, roughly the size of a compact desktop, generated a total of 1,519 watt-hours of electricity, and 57 out of 60 of the water spinach seeds sprouted and grew normally to 18 cm height.

In total, about two litres of water were condensed from the hydrogel over the two-week period.

The team’s goal is to “create an integrated system of clean energy, water, and food production” that can be commercialised. But first they plan to create a better hydrogel that can absorb more water from the air.

SMARTER, CHEAPER DESALINATION

Staying with the theme, we next turn to one of the latest advances in large-scale desalinationboth of seawater and brackish water, based on harnessing solar energy.

According to a largely MIT-based team of scientists, many such efforts have run into problems with fouling of equipment caused by salt build-up, which often adds complexity and expense.

Working out of the Massachusetts Institute of Technology in the US and in China, the team has come up with what they claim is a solution to the problem of salt accumulation – and in the process developed a desalination system that is both more efficient and less expensive than previous solar desalination methods.

The process could also be used to treat contaminated wastewater or to generate steam for sterilising medical instruments, all without requiring any power source other than sunlight itself.

Many attempts at solar desalination systems rely on some kind of wick to draw the saline water through the device, but these wicks are vulnerable to salt accumulation and relatively difficult to clean.

So, the team focused on developing a wick-free system instead.

Aside from dealing with the clogging issue, another aspect of the MIT team’s decision to work with “really low-cost, almost household materials”.

So far, the team has proven the concept using small benchtop devices, so the next step will be starting to scale up to devices that could have practical applications.

Based on their calculations, a system with just one square metre of collecting area should be sufficient to provide a family’s daily needs for drinking water and that materials required to manufacture would cost just $4.

QUEST FOR BETTER BATTERY

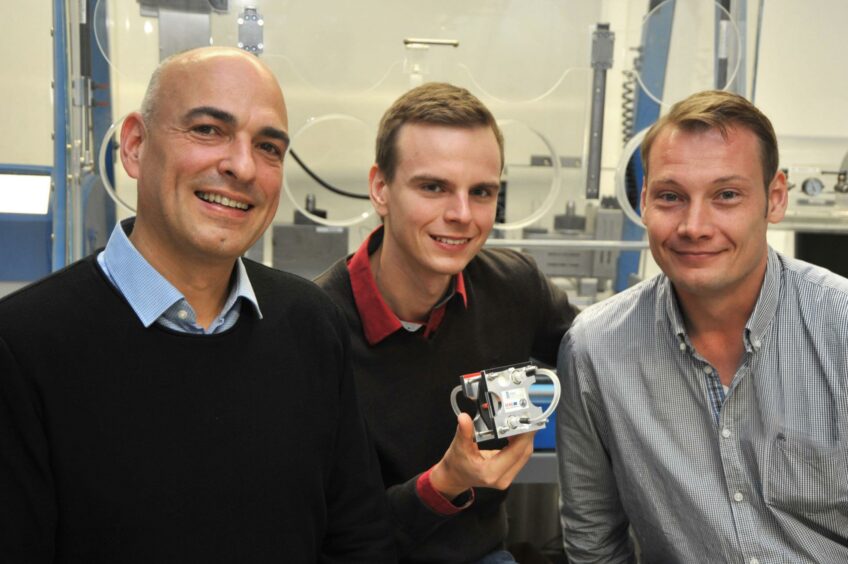

EV has checked out a number of ‘better’ battery concepts over the past 20 or so years and most appear to have come to nothing. So will a new type of plastic battery being worked on at the University of Jena in Germany – and which might provide a large-scale storage solution for electricity generated by wind farms and solar arrays – actually hack it?

At Jena, scientists have developed a battery containing organic polymers that can cope with the fluctuations that result in renewable energy generation due to changing weather conditions.

“This kind of battery … the ‘Redox flow battery’ … is perfect for storing large amounts of energy,” said Ulrich Schubert, who is director of the Centre for Energy and Environmental Chemistry at Jena.

“The new polymer plastic-based batteries can store almost as much energy per kgs as a lithium battery. But because plastics are lighter, we need a larger volume to store that energy.”

The Jena battery is also said to be greener than others that traditionally rely on rare or toxic metal compounds, such as lead and lithium.

For example, vanadium salts are dissolved in acid to produce a traditional ‘redox flow battery’. But with this battery, polymers are used in a liquid salt solution.

“Inside our ‘Redox flow battery’, we’ve dissolved an active material, small molecules or polymers. We can compare it to a little bit like how we dissolve salt when we’re cooking pasta or putting sugar in tea,” said Martin Hager, leader of the Jena Polymers & Energy Group.

So far, around one million euros have been poured into the project of which 800,000 euros came out of the EU’s Cohesion Fund which, because of Brexit, UK universities are denied access to.

SEARCH FOR 50-YEAR PV

Finally in this round-up, we jet to the US and the National Renewable Energy Laboratory where a major effort is going into building a better PV module. Solar panels are hugely popular but they wear out.

OK, but what makes for a good solar module? A few things are obvious: high energy yield, low cost, and reliable in the field.

But every panel manufactured to date degrades and produces slightly less electricity over time as they are exposed to outdoor conditions over the years.

A major question in the solar energy industry is exactly how much we should expect solar modules to degrade each year (generally 0.5%–1%) and when they will eventually degrade so much that they no longer produce adequate power (often about 20% loss from their original output) or become unsafe.

For modules built today, life expectancy is probably 30 years. Each additional year makes the cost of electricity from that module cheaper and means we will need to mine or recycle fewer raw materials to reach our clean energy goals.

Could research push that age of retirement to 50 years? It would certainly make a valuable contribution to creating a sustainable, circular energy economy.

That is the question that is driving NREL’s DuraMAT quest that started back in November 2016 with funding from the US Department of Energy’s (DOE’s) Solar Energy Technologies Office (SETO).

The Durable Module Materials (DuraMAT) Consortium is a multi-laboratory consortium that involves a long list of state and commercial labs and university research facilities across the US.

After five years of researching solar module reliability and awarding $30 million in high-impact projects, DuraMAT was awarded an additional $36 million by SETO for six more years of funding starting in 2021, as the consortium continues its focus on five core objectives intended to accelerate a sustainable, just, and equitable transition to zero-carbon electricity generation by 2035.

“If solar is going to expand and become this ubiquitous technology that we have across our power system, on our houses—and be responsible for 40% of our electricity generation—old technologies are not enough,” said Teresa Barnes, a senior researcher at NREL and director of DuraMAT.

“PV modules need to be made more efficient, less expensive, and more sustainably at much larger scale. But we also need to know that these new modules—whether they’re new module designs or new cell technologies like bifacial or tandem cells—will perform predictably in the field.”

DuraMAT is exploring ideas that could extend solar module lifetime up to 50 years. And it is looking at new variations of module and cell technologies, such as bifacial modules that also collect reflected light on their backsides, or new, high-efficiency cells that require advanced packaging to survive for longer than 30 years.

NREL reports that the next, six-year phase of DuraMAT is off to a strong start. Many projects having already been awarded from the current $36 million funding pot.

“Solar needs to keep improving, and product development cycles can be a lot faster than reliability testing cycles,” said Barnes.

“We need to find a way to assess reliability and durability at the speed of product development as the industry scales up rapidly.”

© Ann Gunther - Friedrich Schiller University Jena (FSU Jena)

© Ann Gunther - Friedrich Schiller University Jena (FSU Jena)