US drill-bit manufacturer BlueFire Equipment Corporation of Houston is to manufacture equipment using 3D printing.

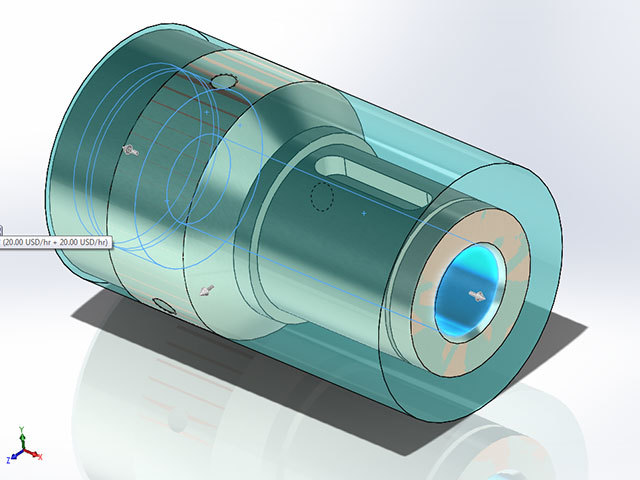

BlueFire has passed a significant milestone on that road by completing development of a digital model of its proprietary polycrystalline diamond cutter (PDC) drill bit.

The company was established in 2008 and is using Texas-based SolidWorks to develop the 3D computer aided design (CAD) software.

By incorporating this leading edge technology, BlueFire expects to achieve considerable cost savings compared to traditional manufacturing methods and expand its engineering capabilities.

3D scanning works hand-in-hand with the 3D printing process. Scanners analyse a physical object to collect data on its shape, size and appearance using a laser or light to measure the distance between the scanner and the object. The captured data is then turned into a digital file used to print a 3D object.

The manufacturing process used for 3D is different.

Traditional engineering manufacturing processes are based on “subtractive manufacturing”, which relies on the removal of material to create something. The lathe used in machining is a classic example of the subtractive process.

Additive manufacturing, or 3D printing, is a process by which three-dimensional objects in a diversity of shapes are manufactured by adding material using digital models.

Metallic, plastic, ceramic or composite materials can be employed using this process, which involves building the required object by adding successive layers of material to achieve the desired shape.

3D printing uses a variety of different types of technologies. Stereolithography (SLA) focuses a beam of ultraviolet light on to a vat of liquid photocurable resin, drawing out the 3D model one layer at a time.

Fused Deposition Modelling (FDM) produces an object by extruding a stream of melted material to form stacked layers. Selective Laser Sintering (SLS) uses a laser to fuse powdered materials layer by layer to form the object.

As for BlueFire, its bits employ large cutter face volumes for rapid drilling of shales, sandstones, limestones and sticky clays.

These bits utilise PDC cutters for improved ROP (“rate of penetration”) and are designed using directed ports to accelerate cleaning and optimise cooling.

Recommended for you