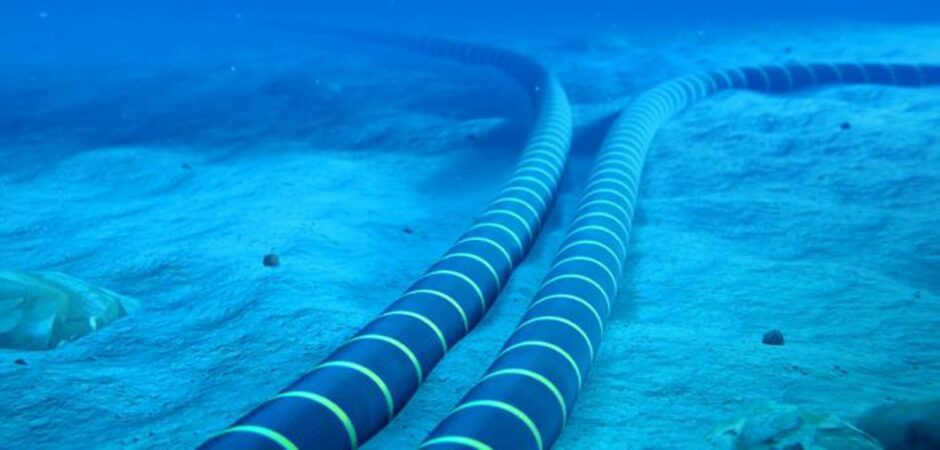

Subsea cables are, essentially, the arteries of offshore wind, critical to the beating heart of our energy transition.

Indeed, the subsea cable sector for offshore wind has a potential, estimated value of over £100 billion across manufacture and installation over the next ten years.

Their performance and reliability are therefore paramount, not only to developers and the industry, but to the whole country which will increasingly rely on the power that passes through them.

But failure of these cables is all too common, to the point that the cost of insuring them is becoming prohibitive. If these critical components become uninsurable, offshore wind projects around the world will be derailed, making global 2050 net zero targets completely unachievable.

The Global Underwater Hub (GUH) is taking an industry-wide approach to exploring the reasons for cable failure and addressing the lack of standards and guidelines across the lifecycle of offshore wind subsea power cables.

With the shift from fixed to floating offshore wind, where the dynamic nature of floating cables is even more challenging, the trade body for the underwater industry is leading the charge to bring the industry together to set global standards that will improve the performance and reliability of subsea cables and place the UK firmly on the radar as a centre of excellence for reliable and high performing dynamic cables.

Globally, over $800bn of investment in offshore windfarms is anticipated by 2030 and, for the world to hit net-zero emissions by 2050, the generating capacity from offshore wind must increase by a staggering 1,120 GW This scale of expansion can only be achieved by installing and maintaining thousands of miles of reliable cables.

The critical issue of cable reliability, and therefore insurability, must be addressed as a matter of urgency and GUH is taking an industry-wide, holistic approach to finding solutions which can be implemented as offshore wind increases in scale and technical capability with higher voltages and dynamic elements.

The organisation, which represents the UK’s £8bn underwater industry, believes the UK can and should become a global leader in subsea cable technology, particularly with regards to dynamic cables for floating offshore wind.

The challenge of insuring cables was laid bare by insurance experts at a recent GUH event with one claiming that 85% of the total value of offshore wind claims relate to subsea cables. Most insurers are losing money underwriting cables with the average settlement claim being £9m. Another broker warned that the high number of cable claims is affecting capacity and coverage and the cost of repairs typically runs into millions with warranties rarely covering the high cost of business interruption.

According to one developer, the cost of insuring a 1.2GW offshore windfarm over its lifetime is in the region of £350m and insurance brokers estimate that the costs of floating offshore wind will be 30% higher than fixed bottom ones.

At a GUH-organised Subsea Cable Insurance Workshop earlier this year, it became apparent that there are inherent issues affecting the performance and reliability of subsea cables that are within the industry’s control. Failures could stem from any stage in the cable lifecycle – from design to manufacture, handling and installation, through to operation and maintenance.

Identifying potential weak points along the lifespan of the cable is imperative to ensuring these key components of offshore infrastructure operate robustly and efficiently to bring clean, green renewable energy ashore.

Representatives from government, cable insurers, developers and operators, cable manufacturers, risk management consultancies, and engineering, installation and specialist maintenance companies attended the workshop. Common themes were identified across each stage of the lifespan, as well as concerns which may originate in one stage but have an impact on another.

These common themes and concerns demonstrated the need, and the desire, for a set of industry led and recognised standards encompassing the life of the cable that would be adopted by developers, suppliers, contractors, warranty surveyors and others and accepted by insurance bodies.

Systems-based design, standards development, data sharing, quality control, risk allocation and industry collaboration are of critical importance in reducing cable failures.

There is an urgent need for better information sharing and a move away from a siloed approach, that is often ‘secrecy driven’ and ‘NDA heavy’. This data sharing is one of the main challenges that must be overcome. Introducing shared learning, data logging and increased transparency will create a more open environment for best practice to be developed

This quest for quality and reliability needs to be driven at the same pace as the drive for efficiency and speed, and considered from both a capital and operational cost perspective.

GUH’s recently established Subsea Cables Industry Forum, whose members are drawn from companies involved in every stage of the cable lifecycle will help establish an industry wide approach to best practice and improve the quality, reliability, and therefore insurability, of cables which is paramount to achieving our offshore wind ambitions, particularly in the nascent floating offshore wind arena.

Interested parties can hear more about GUH’s industry-wide approach to tackling subsea cable reliability at the Cables 2023 conference on 20 September at the Chester Hotel in Aberdeen. Places can still be booked here.

Recommended for you

© Supplied by GUH/ Newsline media

© Supplied by GUH/ Newsline media