The UK’s decarbonisation goals are undoubtedly ambitious and will require a comprehensive, multi-faceted strategy if the country is to meet its net zero obligations.

Though hydrogen is regarded as a key pillar in the nation’s energy transition plans, a slow rollout of necessary infrastructure could stall momentum in critical industries such as transport and logistics.

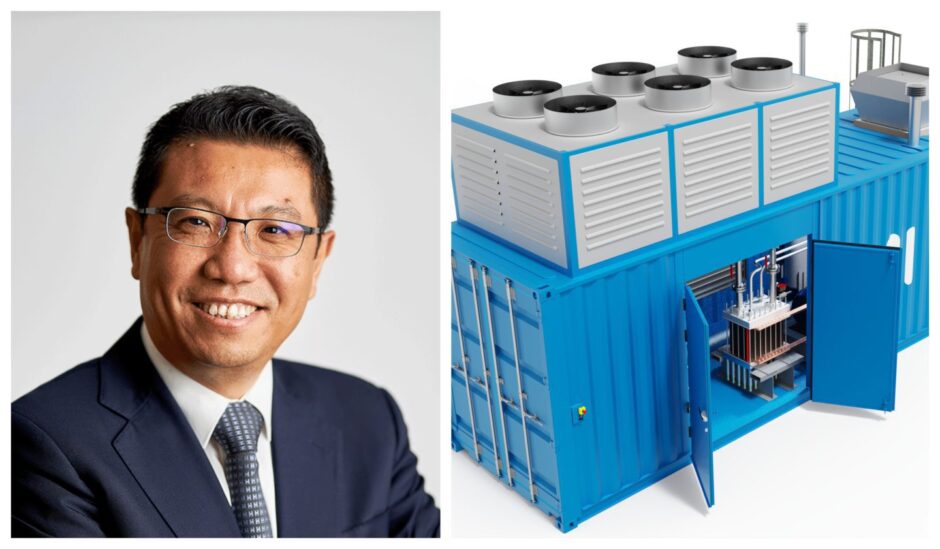

Jackie Hu, CEO of Automation at IMI, explores why decentralisation may hold the key to unlocking hydrogen’s potential, and how applied knowledge of flow control systems can accelerate sustainability efforts.

Hydrogen’s potential role in decarbonising industry has long been acknowledged, particularly for the transport and logistics sectors. This was underscored by the 2015 Paris Agreement, which affirmed its status as a significant factor in future emission reduction plans.

Yet despite high expectations, progress has been stop-start. According to 2022 projections, hydrogen was only on track to constitute five percent of the energy mix by 2050, falling considerably short of the agreement’s predictions. Further analysis is required to explain this disconnect, and the factors that lay behind it. However, the UK Government’s latest Hydrogen Strategy Update identifies one reason, voicing concerns that the limited rollout of existing hydrogen infrastructure could hinder the fuel’s more widespread uptake.

Despite this, the update still identified the heavy transport and logistics sector as a key driver of hydrogen uptake in the medium- to long-term. The question therefore remains over how this gap can be bridged, especially with industry forecasts predicting exponential growth in the global market for hydrogen-fuelled vehicles such as HGVs and forklifts. With the market expected to expand prolifically from $1.19bn in 2021 to $36.9bn by 2030, concerns will undoubtedly be raised over how larger fleets can be refuelled remotely.

This is clearly a significant challenge, but progress is being made. For instance, Centrica is currently carrying out a first-of-its-kind trial injecting hydrogen into its grid-connected Brigg power plant during peak times to lower overall carbon intensity. The success of this project could potentially pave the way for more low-carbon power generation projects utilising existing grid infrastructure.

Focus on Decentralisation

Yet even if the trial is successful and hydrogen effectiveness in larger power facilities is proven, accessibility will remain a hot topic. Indeed, even though the latest Hydrogen Strategy Update emphasised co-locating supply and demand through large-scale hydrogen storage and integration, any plans could take years to come to fruition. Ultimately, the success of hydrogen as a fuel source will hinge on its ease of availability at the point of use.

Proton exchange membrane (PEM) electrolysis presents a promising way to do this while reducing emissions. PEM technology enables sustainable production of pure hydrogen, unlike other methods reliant on fossil fuels. These types of hydrogen – known as blue, grey, black or brown hydrogen – actively add to a business’s overall carbon footprint and still constitute the majority of hydrogen generated in the UK today. By contrast, the ‘green hydrogen’ produced by PEM electrolysis generates electricity using renewables, rather than fossil fuels. With increasingly efficient PEM-based technologies now more widely available, businesses now have access to a commercially viable and sustainable hydrogen production method for the first time.

Overcoming Obstacles

Though such advances paint an encouraging picture, obstacles remain in the transition to low-carbon hydrogen. The fact that the National Grid will still be dependent on fossil fuels in the short to medium-term must be factored into any hydrogen production projections, as well as the rising costs afflicting all industries. Taking this into account, decentralised electrolyser technology presents a more affordable option for on-site hydrogen production.

For businesses in the transport and logistics sector looking to upgrade fleets to hydrogen powered vehicles, its more immediate availability may help stakeholders circumvent the delays in nationwide infrastructure rollout cited by the latest Hydrogen Strategy Update. In a business landscape where the expansion of ultra-low emissions zones will hugely impact everyday operations, the value of being able to both upgrade existing fleets and affordably produce fuel on-site cannot be overlooked. Without decentralised production capabilities, fuel cell vehicles may become only an option for companies with large financial reserves. To ensure a smooth and wide-ranging transition from fossil fuels, this sort of exclusionary situation must be avoided.

Turnkey solutions offer a way of mitigating cost barriers, providing integrated and modular systems that can be deployed as a package with minimal disruption and lower capital expenditure. Developed by companies such as IMI by applying pre-existing knowledge of process systems to the hydrogen sector, these systems differ from other electrolyser technologies as they can be housed in a standard shipping container.

Because of this, they can be accessed and deployed by smaller businesses much faster than potential alternatives. Additionally, digital twin analysis can be used to optimise efficiency and equipment performance, further enhancing the viability of smaller-scale, decentralised hydrogen production facilities of this kind. The fact the container can be fitted with fuel cells and storage systems also helps organisations avoid issues that arise after hydrogen has been extracted. For businesses that lack the facilities to capture carbon dioxide when reforming the steam from natural gas, this could be invaluable.

From Projections to Reality

It must be noted that these projections are not based on untested or theoretical technologies. Larger-scale PEM electrolysis systems do already exist, but due to their size and cost, they are not widely accessible. By contrast, modular, scalable and affordable turnkey solutions could play a vital role in ensuring widespread adoption of clean hydrogen in the transport and logistics sector.

Yet the widespread applicability of decentralised energy generation solutions goes further than this. For transport and logistics businesses based in harder-to-electrify and rural areas, deployable turnkey systems can allow an easier transition to alternative fuels regardless of location. That this is possible while also lowering storage and transport costs for affected businesses further underlines the appeal of modular, turnkey systems.

Overall, removing barriers to access green hydrogen must be a priority, especially given already-established frustrations over infrastructure rollout identified in the Hydrogen Strategy Update. Decentralised solutions such as PEM electrolysis will be essential for accelerating decarbonisation efforts. Adopted at scale, it will allow the transport and logistics sector to take action now to reduce emissions, rather than waiting for infrastructure projects to be completed.

Recommended for you

© Supplied by IMI

© Supplied by IMI