The $28billion Stage-2 of the huge gas-condensate, BP-led Shah Deniz project offshore Azerbaijan has taken an important step forward with the award of contracts together worth more than $1billion to the local economy.

The contract, covering fabrication of the jackets for the two planned offshore platforms, pin piles and subsea structures, has been awarded to a consortium comprising BOS Shelf, Saipem and Star Gulf FZCO.

The deal is worth $750million, was awarded under an existing master frame agreement and covers:

o Construction of two 8-legged single batter jackets – both 110m in height and weighing 13,400 and 12,300 tonnes including the flotation tanks.

o Fabrication of 2,300 subsea structures with a total weight of 30,000 tonnes. In particular, the subsea fabrication scope includes eight sub-sea isolation valve structures, ten flow-line termination assemblies, 80 walking anchors, 100 subsea tie-in piping spools, 100 pipeline crossing supports, 1,000 concrete mattresses and 1,000 tonnes of current transfer zone foundations.

The huge subsea package represents a milestone in its own right.

According to Gordon Birrell, BP’s regional president for Azerbaijan, Georgia and Turkey (AGT), the subsea package is potentially transformational for Azerbaijan.

“We are pleased that this contract underpins our plans to deploy subsea production technology in the Caspian Sea for the first time.

“The use of this technology in Azerbaijan will open up new opportunities for oil and gas developments, and allow the country to remain at the forefront of technological developments in our industry”.

All construction and fabrication work under this contract will be undertaken at state oil company Socar’s Baku Deepwater Jacket Factory (BDJF).

The contract is expected to generate up to 2,750 local jobs at peak and some 8million man-hours of actual construction work, all of which will be carried out in-country.

Fabrication activities are expected to complete in 2017.

Turning to the second big package of work just awarded, this covers the actual subsea production systems package for Shah Deniz Stage 2.

The estimated value of this contract is $394million and it has been awarded to FMC Technologies.

The scope of work under this contract includes the supply of equipment for the first two production clusters consisting of subsea manifolds, associated controls and connection components.

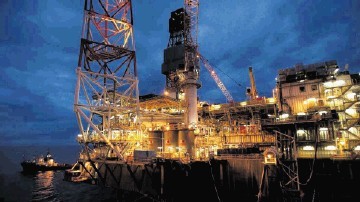

Shah Deniz is one of Azerbaijan’s most important offshore fields, lies 70km south-east of Baku city in water depths ranging 50-600m and covers an area of about 860 sq.km.

The resource was discovered in 1999 and ranks as one of the world’s largest gas-condensate fields, with 40trillion cu.ft (over 1trillion cu.m) of gas in place plus around 1.5billion barrels of condensate.

Platform-based Stage 1 cost around $6billion and started operations in December 2006. It has the capacity to produce about 9billion cu.m of gas per annum and about 50,000 barrels a day of condensate.

It was during 2009 that preparations for Stage 2 started. Initial expected capex was $16-20billion and an estimated 12bcm would be added to production.

Mid-2010 saw a memorandum of understanding signed between Turkey and Azerbaijan. Besides covering gas prices, the MOU laid the ground for Stage 2 with a view to production starting in 2016.

Gas from the project would be transported through the 690km South Caucasus Pipeline, which extends to the border between Georgia and Turkey.

Gas sales and transit agreements were eventually signed in October 2011 with Botas, the Turkish pipeline company, and the Turkish Government.

It was in April 2012 that news of the FEED (front-end engineering and design) contract emerged. The brief was to cover two new bridge-linked production platforms; 26 subsea wells; 500km of subsea pipelines laid in 550m of water; a 16billion cu.m per annum upgrade for the South Caucasus Pipeline (SCP); and expansion of the Sangachal Terminal.

December last year saw BP and its partners make the final investment decision to proceed with Stage 2 of the development.

This confirmed that Stage 2 would involve the drilling and completion of 26 development wells and the construction of two bridge-linked platforms along with the construction of onshore processing and compression facilities at Sangachal.

First gas was targeted for the end of 2018 and the further development was expected to allow the increase in production of condensate to 120,000 bopd from the current 55,000. Additionally, Statoil intends to farm-out 10% of its 25.5% participating interest to Socar and BP at 6.7% and 3.3% respectively in return for a consideration of $1.45 billion.

Then, at the end of December, KBR said it had been awarded the detailed engineering and procurement support services work package, the work to be carried out near London.

Another key contractor with significant involvement was J P Kenny, which is BP’s subsea engineering and project management services (EPMS) contractor for Shah Deniz. Its scope of work was to include overall subsea system design and responsibility, functionality and technical assurance for the subsea production system, flowline and export pipeline design, detailed process and flow assurance assessments.

As tends to happen with major projects, a variety of key contracts tend to be awarded around the same time. An excellent further example in this case is the fabrication package awarded to the Amec Tekfen Azfen (ATA) consortium, which has a world-class fabrication yard on the coast south of Baku.

It was late January when Amec announced that the consortium had been awarded a $974million contract covering project management, fabrication, load out and offshore hook-up and commissioning of the topsides units of the two Stage 2 platforms, comprising the production and risers platform and quarters and utilities platform.

Construction works have started with completion expected in 2018.

Amec has worked for BP-operated projects in Azerbaijan for 16 years and, as part of the ATA consortium, has successfully completed three major platform topsides as well as providing offshore asset support services in the Caspian.

A few weeks after the platform fabrication contract came further good news with the Shah Deniz and South Caucasus Pipeline consortia awarding of key contracts for the development of the Shah Deniz Stage 2 and South Caucasus Pipeline Expansion (SCPX) projects.

The $528million contract for the construction and commissioning support of the SCPX project facilities in Georgia went to the Bechtel Enka joint venture.

The $174million contract for pipeline and facilities engineering and project management services for SCPX went to Chicago Bridge & Iron UK (CB&I).

The contract for the initial phase of the subsea and pipeline engineering and project management services, amounting to $57million, went to Wood Group Kenny.

This review just scratches the surface of Shah Deniz Stage 2. Many more contracts have been awarded and there are others to come. Energy will revisit this project at some point in the future.

Recommended for you