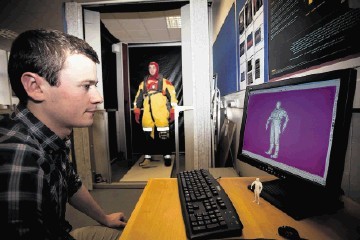

A groundbreaking research project to measure offshore workers’ body size and shape with 3D scanners in Aberdeen has assumed a dramatic relevance as a result of the Civil Aviation Authority’s diktats regarding North Sea helicopters.

Launched in December 2012, the two-year study is now around the half-way stage and is intended to inform the future design of safety equipment, survival clothing and space requirements on offshore installations and helicopters.

The UK offshore industry had been planning improvements to safety standards and equipment as applied to offshore workers for some while and is a core reason as to why the Robert Gordon University work was commissioned.

The research goes well beyond providing the first size survey of the offshore workforce for nearly 30 years – it will generate an ongoing capability for measuring the size and shape of the offshore workforce whenever the industry requires.

This is hugely important, not least because those of us who have families will by and large be familiar with the fact that offspring tend to grow to be taller and broader than their parents.

The planned sample size of the study is 600 offshore workers. Data has so far been collected from 250 or so volunteers, but the project’s leaders are keen that others step forward . . . no less than around 350 individuals.

The work is being led by researchers at Robert Gordon University’s (RGU) Institute of Health and Wellbeing Research (IHWR) in collaboration with experts from Oil & Gas UK.

Project leaders Dr Arthur Stewart, knowledge exchange co-ordinator for IHWR, and Dr Graham Furnace, medical advisor for OGUK, conceived the project in 2011 and have built an experienced team to support the research.

The objective is to design and implement a systematic assessment of three-dimensional measurements on a sample of around 600 offshore workers.

The data will then be used to inform all aspects of offshore ergonomics and health and safety, from emergency helicopter evacuation and survival suit design to space availability in corridors and work environments. The findings are due to be published in 2015.

Preliminary findings for the study include quantifying the volumetric increase associated with wearing a survival suit, helpful for estimating space in enclosed lifeboats, and the standing footprint required by different sized individuals which is useful to know for mustering.

The following is a measure of how people have changed over the past 30 years.

o In 1985, when the last study was undertaken, the average height and weight of the offshore workers was 175.6cm and 76.6kg respectively, and 95% of workers weighed less than 93.2kg, while the heaviest worker weighed 115kg

o By 2009, the average weight of the workforce had increased to 90.9kg, representing a 19% gain or 6kg per decade

o By 2009, 5% of the workforce weighed more than 115kg and the heaviest 1% weighed more than 128kg, with the heaviest individual weighing 158kg

o According to RGU, it is highly doubtful if the 1-2cm average height increase across the UK population during this time can explain much of the observed weight gain

Dr Stewart said that the research team had enjoyed a “very positive year” since starting active measuring of offshore workers for the study in March 2013.

“We are now well into the third phase of the project with more than 2,200 body scans acquired on nearly 250 individuals across all phases,” he told Energy.

“These have been gathered at RGU’s Garthdee campus, oil company headquarters, the heliports at Aberdeen and even a North Sea oil rig.

“Understanding this change in size and space requirements for the offshore workforce is important as their current workplace is designed for personnel as they were a quarter of a century ago.

“The last body size survey of offshore workers was undertaken in the mid 1980s and since then the average weight of the workforce has risen by 19%.

“As a consequence the size and shape of the offshore workforce has increased to an unknown level.

“Knowing the actual size of the workforce, together with size increments imposed by different types of clothing, will enable space-related risk to be managed and future design for space provision optimised.”

Earlier this year, RGU KTP associate Robert Ledingham and Oil & Gas UK’s Moira Lamb gave a number of presentations about the project, including a live demonstration of the scanning technology, to hundreds of industry delegates at the Step Change in Safety Conference in Aberdeen.

More than £150,000 in funding for the project was secured through a combination of a Technology Strategy Board Knowledge Transfer Partnership Grant as well as support from several OGUK member companies.

Aberdeen company Survival One (Survitek Group) has also donated a number of the very latest survival suits for use in the project.

The full results for a representative sample of the workforce will be available in 2015 and will facilitate future designs of a range of factors from survival suits to accommodation modules.

If you would like to participate in the study, please contact Arthur Stewart on (01224) 262551 or e-mail: a.d.stewart@rgu.ac.uk

Recommended for you