North Sea operators could harness the wind to enhance oil recovery from depleted reservoirs according to DNV GL. Limited use has been made of small turbines to augment power generation on some platforms, but this proposal is much more radical.

The classification organisation come risk management specialist wants companies on either side of the maritime renewables/offshore oil and gas divide to come together in a joint industry project to explore the idea.

It is totally in tune with the ethos of the All-Energy conference started in Aberdeen 14 years ago and which has been whipped away from Europe’s Energy Capital to Glasgow, supposedly for three years.

Initial studies at DNV GL suggest that it will reduce the cost of water injection, avoid costly production platform topsides modifications and reduce greenhouse gas emissions.

Engineers at the organisation reckon there is an opportunity to develop a new generation of autonomous injection systems needed to increase reservoir pressure, so boosting hydrocarbons recovery.

According to DNV GL, there are “clear indications” that such a wind-powered water injection system could reduce both CAPEX and OPEX and drive innovation of new technology.

Moreover, it could be installed without costly retro-fittings on the platform, provide access to systems normally located subsea, increase the flexibility of injection location and reduce the installation time. The system would also be easy to move and use at new locations after the closure of a well or field.

“We want to take this concept further together with both the wind energy and O&G industries and invite them to participate in a JIP to carry out an in-depth study – ‘WIN WIN – WINd powered Water Injection’,” said Johan Sandberg of DNV GL’s offshore renewable energy business unit.

“The combination of the two technologies can open up an era of synergies and mutual benefit for both industries. I see this as a very important part of the oil and gas industry’s work to reduce cost and with less emissions as a positive effect.”

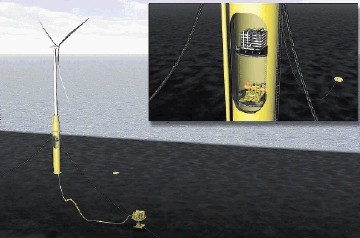

DNV GL’s idea is to integrate the compressor and water treatment equipment into the sub-structure of a floating wind turbine.

The view is that combining the newest developments within offshore wind power and enhanced oil recovery could create a highly beneficial partnership.

Floating turbine technology has been selected as they apparently offer “one of the most interesting sources for offshore power generation, allowing relatively stable production, and flexibility regarding locations and water depths”.

This power can be used with a variety of water injection technologies, ranging from raw seawater injection as the simplest to LowSal water injection (low salinity water from a reverse osmosis process) as the most complex.

Christian Markussen, from the oil and gas side of DNV GL, said: “Our studies show that such a stand-alone system can quickly become cost competitive to traditional solutions for injection wells far from the platform, and even more when one considers the retrofitting water injection equipment into an existing facility and cope with the disruptions that this modification can have on production.

“Operators can obtain a new and cost-efficient way to develop marginal reservoirs and enhance production in mature fields.

“The financial benefits will vary depending on several factors, such as the reservoir characteristics and step-out distance from the production well.

“Traditional injection systems normally have a significant CAPEX investment, CO2 tax, and exposure to fuel costs, and hence provide a substantial incentive for assessing alternative solutions.”

On the basis of what DNV GL has said so far, the North Sea operator possibly best placed to play a prominent role in turning an idea into reality is Statoil as it is a major producer, plus it owns the intellectual property for both the Hywind and Sway floating turbine technologies.

Recommended for you