No matter where the oil price is going in the next 12-18 months, this must be the time for the industry to look afresh at the way it operates.

For the reality is that while we in Aberdeen may hope for a bounce back of the Brent index, the rest of the world benefits from low oil prices: consumers save at the petrol pump, and industries on the balance sheet. All that creates an increase in GDP, spending power and new jobs, so what isn’t there to like about a lower price per barrel?

The reaction of some parts of the oil industry to the recent fall in prices has been entirely predictable. Find cost reductions by setting a target or enforce a mandatory cut across the board.

Regrettably, as a consequence, we have seen instant head-count reduction, which may seem good sense in the short term, but impacts company loyalty in the long term.

We’ve also witnessed the squeeze on contractors as the big corporates unilaterally impose a rates reduction, forcing the cuts to cascade through the supply chain.

To my mind, the risk of carrying on as we always have is to miss an opportunity. The industry should be jumping on recent events as a trigger for change and setting its structural operating cost at a sustainable level for the years ahead – one that assumes a low oil price as its base.

Examples of greater efficiency exist within the sector, however there is much to be learned from other sectors. So, time to think afresh.

For instance, Accenture, the organisation which I work for, has developed a cost reduction approach for exploration & production companies following interviews with E&P service providers, which prompts operators to work directly and collaboratively with their suppliers to reduce costs, rather than cut them off.

We work with supply chain companies generating hypothesis on what can be done in the short, medium and long term based on established risk analysis.

Knowing what and when new services or technologies could be available means greater efficiencies and lower budgets can be built into the operators’ forward plans.

We applied this approach to decommissioning costs at a large North Sea operator, justifying an auditable 20% reduction of those costs. This is about partnering to solve cost challenges, not creating unnecessary divisions.

In the face of intense and immediate cost pressures, workforce productivity and talent retention become key issues.

This, therefore, should be the right time to accelerate the development of a workforce of the future that is both agile and multi-disciplinary, augmented by the digital technologies we are accustomed to in our everyday lives.

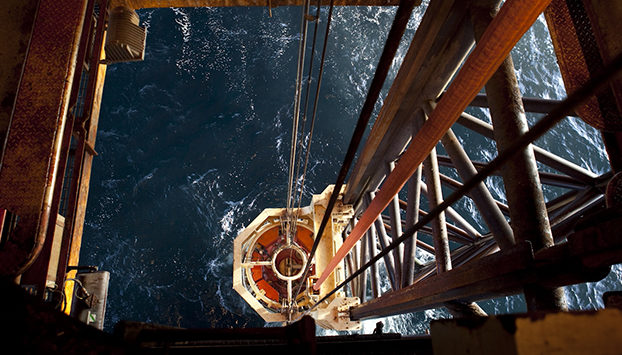

Cross-skilling offshore workers, for instance, would increase their productive time. For example, deploying WiFi on an offshore oil rig and combining this technology with mobile devices, like helmet mounted ATEX zone 1 compliant cameras (a rugged version of smart glasses), would connect a generalist and versatile offshore worker with a deeper expert onshore, allowing a number of tasks to be performed remotely via a sort of a human “avatar”. This is already happening but in a low key way.

This remains an industry with too many bespoke solutions, even accepting that each platform and offshore environment is different.

By defining standards across the industry wherever possible and progressively implementing these during an equipment replacement phase we would see a huge difference in efficiency.

The same goes for using big data and analytics capabilities to optimise monitoring and maintenance practices. Better predictability also has the knock on effect of improving safety.

And why not modernise logistics and warehousing by taking advantage of digital technologies, from radio-frequency identification to drones and robots?

Another well-established business service that the industry has been traditionally reluctant to consider is outsourcing, though it was a feature of the late 1990’s downturn and immediately prior CRINE/CRINE Network initiatives.

Yet, at a time when oil companies need to put their focus on core areas of expertise and developing the talents that will shape their future, getting non-core elements of the business, such as finance and accounting, IT and HR, from specialised providers can lead to huge efficiencies, cost savings, and long-term value.

Quality, professional outsourcing services, such as procurement, can be linked to real commercial benefits. External services can be “blended” with in-house teams and scaled up and down to suit variations in demand.

Adopting a business model for support functions, which is set at the most competitive price for those services, is preferable to the delivery of those same services always being dependent on the price of oil.

With the rest of the population scrutinising how the industry reacts to the fall in oil prices, the message should be that it can operate efficiently at this level, not one of alarm. North Sea oil companies can collaborate with their supply chain partners and use their expertise and their commercial alliances to everyone’s benefit.

By looking for structural changes – including a process of standardisation – they will make efficiencies that will last. And by working to maximise the talents of the existing workforce by cross-skilling, a company can motivate, build loyalty and develop expertise.

Doing things the same way that they have always been done will cause the industry to quickly lose the sympathy of a world that likes low oil prices. But by thinking afresh, we capture the opportunity to regain our historical lead for innovation, fuel further growth and re-establish the oil industry as a dynamic and exciting place to work.

Luca Corradi is managing director of Accenture’s energy business in Aberdeen

For more opinion pieces on Energy Voice click here.

Recommended for you