Since the days of Henry Ford and the beginning of mass production, the benefits of ‘standardisation’ have been widely promoted and publicised. The automotive industry spear-headed standardisation and, with it, transformed manufacturing practice forever.

The rationale for standardisation is as compelling as it is simple – we know full well that variation is more likely to cause errors, increase complexity and therefore impact everything from safety to operating costs.

The oil and gas industry has been slower than many to adopt standardisation to the same extent, although some operators have been better than others at embracing the concept.

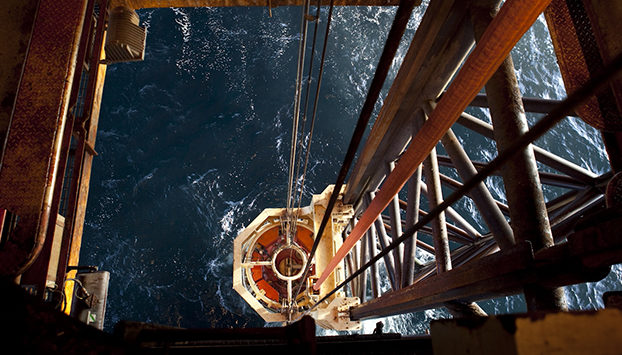

Generally, the industry is still behind the curve. Nowhere is this more evident than offshore when comparing ‘ways of working’ across different shifts where it is not unusual to see a marked change in how things get done with the arrival of a new crew.

OIM’s, OTL’s and supervisors each have their preferred way of doing things. This is not surprising – the absence of a standard and, more importantly, a culture of standardisation, makes this inevitable and leaves individuals with the freedom to develop their own ‘ways of working’.

If it works for you, why change it? The answer is simple; standardisation offers a wide range of benefits including improved production stability, a safer and more predictable work environment, reduced costs as a result of there being less variability and waste.

It also means that when changes are made, the same changes are implemented across the board which also means that intended benefits are similarly realised across multiple assets.

There are two important lessons to be learned from those industries that have genuinely embraced and reaped lasting benefits from standardisation. Firstly, it has to be driven from the top, and that means the very top.

As is evident from well-publicised examples, standardisation is not a passing initiative and neither can it apply to a small corner of the organisation. It’s all or nothing and it’s for the serious players only – those who are committed to changing attitudes and behaviours as much as they are to developing new procedures and playbooks.

Secondly, the case for change has to be compelling for there to be sufficient drive to stay the course. For many industries standardisation and the drive to reduce complexity has been integral to a broader strategy, often involving survival.

Needless to say, an agenda based on ‘survival’ has a way of focussing the mind as well as the resolve.

In the current climate, at sub $50/bbl, the oil and gas industry needs focus and resolve in large measures and it could do worse than channel some of its efforts into tackling longstanding challenges, particularly those that have cultural and behavioural dimensions at their root. However unwelcome the current climate may be, it may just provide impetus and a window of opportunity for the industry to close a widening gap.

The pressures that forced other industries into shifting their paradigms from ‘craftsmanship’ to ‘industrialised’ are the same ones that are rocking the oil and gas industry today. Those operators who make this shift successfully will emerge from the current crisis fitter and better equipped to capitalise on an improved economic situation.

David Delvin leads Hitachi Consulting’s EMEA Oil and Gas practice and has been working as a consultant in the sector for over 20 years.

Recommended for you