Leading marine and subsea firm IMES has invested £50,000 in new technology, expanding its existing service offering for clients in the oil and gas industry.

The Aberdeen-based company, which provides inspection, monitoring and engineering solutions to the global energy, defence and industrial markets, has added the

Viper Maxi MK II wire rope lubricator and Wire Rope NDT equipment to its range of products.

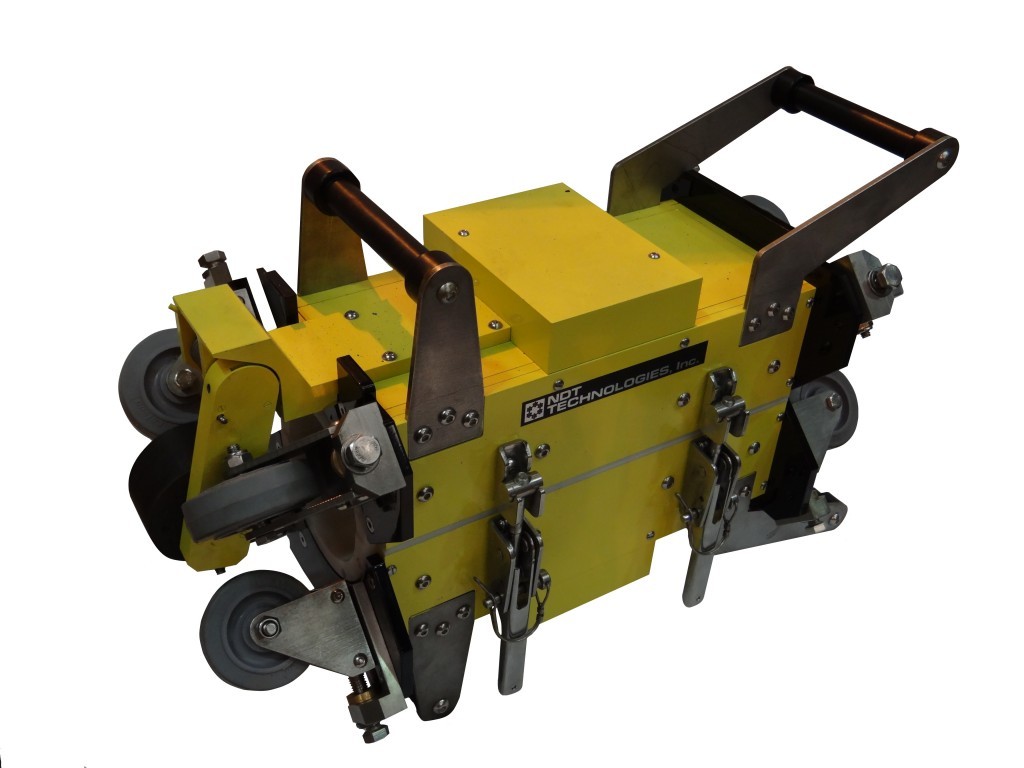

IMES is a UK distributor for Viper, the leading wire rope pressure lubrication system manufacturer, and NDT Technologies, which offers high-quality non-destructive testing of wire ropes.

Previously, IMES could lubricate wire ropes of up to 67mm in diameter, but using the new Viper Maxi MK II, ropes ranging from 8mm to 165mm can be automatically greased at speeds of up to 2,000 metres per hour.

This technology allows ropes to be cleaned and lubricated on site with less wastage, reducing the overall cost of the process and increasing safety by removing the need for manual greasing. Due to its lighter weight, the product can also be installed by one person, rather than two.

The company has launched new Wire Rope NDT equipment, expanding its capability for inspecting ropes from 83mm up to 115mm. The technology provides assurances on wire rope integrity, detecting and measuring both surface and internal faults.

Assessments are performed on site and are unaffected by wire rope lubricant, paint, dirt or plastic sealing material. It has the added benefit of reducing the opportunity for human error by not relying entirely on the human eye, which has the potential to miss defects.

Chief operating officer Jason Smith, said: “We fully expect the Maxi MK II to prove popular across a range of sectors, particularly for crane and shipping operators looking to increase the efficiency of their operations and extend the lives of their ropes.

“The new Wire Rope NDT machine will bring significant improvements to clients’ safety operations in terms of speed and reliability.”

Recommended for you