As the global energy sector evolves to meet increasing demand and security of supply, subsea pipeline tie-ins have become a critical component of offshore infrastructure development.

-

Some Energy Voice online content is funded by outside parties. The revenue from this helps to sustain our independent news gathering. You will always know if you are reading paid-for material as it will be clearly labelled as “Partnership” on the site and on social media channels,

This can take two different forms.

“Presented by”

This means the content has been paid for and produced by the named advertiser.“In partnership with”

This means the content has been paid for and approved by the named advertiser but written and edited by our own commercial content team.

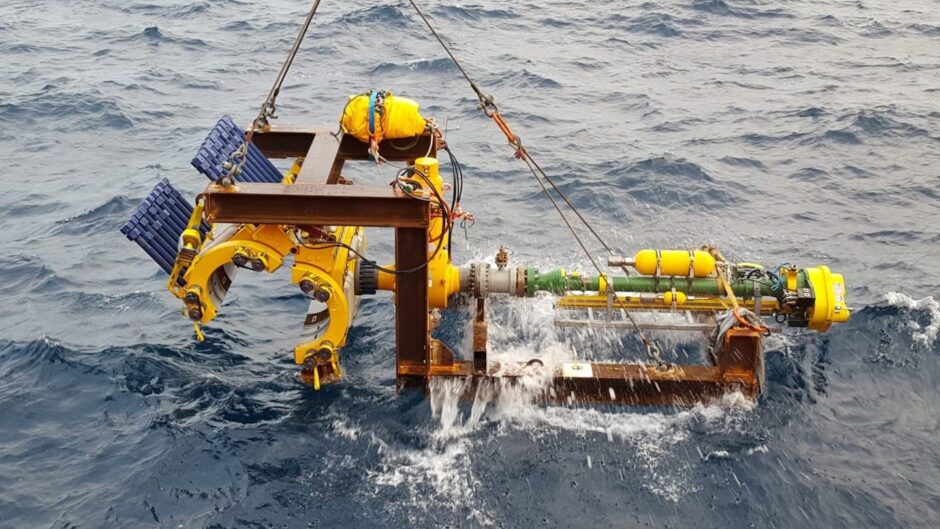

With a growing focus on safety, efficiency and cost-effectiveness, operators are looking for innovative ways to connect new oil and gas fields to existing networks without shutting down production or to re-route pipelines to decommission redundant infrastructure. STATS Group, a global leader in pipeline isolation, hot tapping and connection solutions, is at the forefront of this technological shift with its advanced range of subsea mechanical hot tap clamps and proprietary intervention and isolation technologies. These technologies ensure these critical pipelines remain pressurised ensuring uninterrupted product flow to customers, while tie-ins are completed safely.

Meeting the challenges of subsea infrastructure development

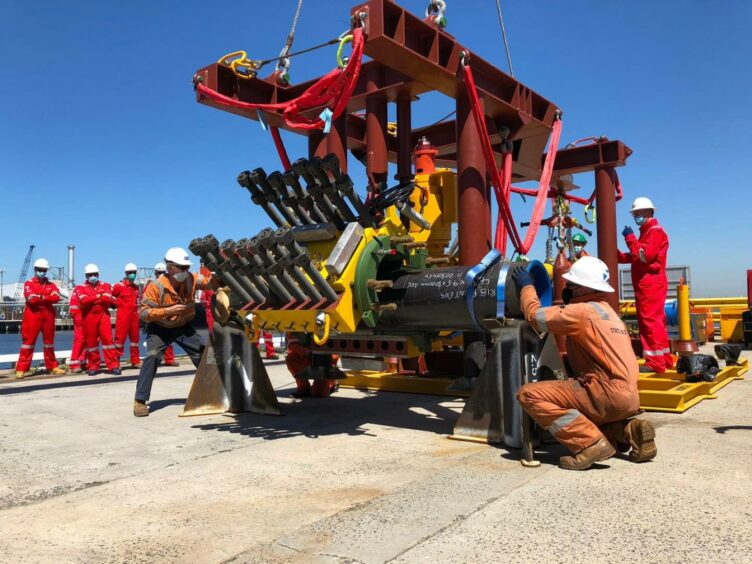

Pipeline owners and operators face significant challenges when upgrading or expanding subsea infrastructure. The traditional method of hyperbaric welding for connecting new pipelines to existing assets poses considerable risks, costs, and logistical hurdles. Hyperbaric welding requires expensive equipment, highly trained diving personnel, and complex safety measures, increasing operational complexity.

STATS Group has developed an alternative solution that addresses these challenges head-on. Their subsea mechanical hot tap clamps facilitate the permanent connection of new branch pipework to existing pipelines without the need for hyperbaric welding or pre-installed tees. These clamps enable hot tapping into a live pipeline under pressure without interrupting production, delivering unparalleled safety and efficiency.

STATS’ clamps can also act as access points for deploying temporary line stop isolation technology, the combination of these technologies significantly reduces downtime preventing operators from decommissioning and then recommissioning the entire subsea infrastructure.

STATS patented BISEP® line stop technology provides a fully proven and monitored dual seal barrier, enabling the safe breaking of containment on pressurised systems in compliance with the highest industry standards. Dual BISEPs can be deployed to provide a mid-line isolation for repair or maintenance without halting operations, as flow is maintained through an integrated bypass.

In addition, the BISEP is the only line stop isolation tool that satisfies the design criteria for DNV Type Approval for Pipeline Isolation Plugs, ensuring safe worksite conditions for divers and the environment during breaking of containment activities. The design criteria satisfies the requirements for Pipeline Isolation Plugs to provide dual seal and isolation in accordance with Offshore Standards: DNV-OS-F101 (Submarine Pipeline Systems) and recommended Practices: DNV-RP-F113 (Subsea Pipeline Repair) and is code compliant with: ASME BPVC Section VIII, Division 2, making it a preferred choice for operators worldwide.

Global success in subsea tie-in projects

STATS Group’s expertise in subsea tie-ins has been demonstrated through successful projects across the globe. From the North Sea to the Gulf of Mexico and Asia, their solutions have proven effective in various operational conditions. Notably, the company is experiencing growing demand in the Middle East, a region poised for significant subsea infrastructure development.

Project Highlights:

Bass Strait, Offshore Australia: STATS supplied an 18” hot tap clamp with a 12” branch and SureTap® hot tap machine to enable a critical pipeline tie-in in the Bass Strait, offshore Australia. This project showcased the efficiency of mechanical clamps in providing a robust flanged off-take while the 18” pipeline remained at 72.5 bar.

Dutch North Sea: STATS supported Petrogas in connecting two gas fields to existing subsea pipelines in the Dutch North Sea to enhance domestic gas supply and unlock natural gas reservoirs of 100 billion cubic feet (BCF). The project involved the supply of a SureTap hot tap machine, 16” and 12” high pressure hot tap clamps both with 8” branched offtakes, designed for 135 bar pressure. The success of this project highlights STATS’ ability to deliver tailored solutions for complex subsea environments.

Norwegian Continental Shelf: Aker BP and Subsea 7 collaborated with STATS to install an 8” mechanical hot tap clamp and SureTap hot tap machine for tying in a new gas lift line to an existing pipeline in Aker BP’s Hod Development. Operating at 143 bar, this permanent clamp unilised rubber seals in a first of its kind on the Norwegian Continental Shelf. The innovative approach eliminated the need for hyperbaric welding, resulting in significant cost and time savings while enhancing diver safety.

Driving innovation in subsea pipeline solutions

The demand for safer, more efficient subsea tie-in solutions is expected to grow as operators worldwide seek to optimise infrastructure and reduce operational risks. STATS Group’s portfolio of mechanical hot tap clamps and proprietary isolation and intervention technologies positions the company as a trusted partner in meeting these needs.

Andy Norrie, Head of Sales and Business Development for Europe at STATS Group, said: “As a trusted partner in subsea pipeline infrastructure development, STATS Group is committed to addressing the industry’s most complex challenges with our market-leading subsea technologies. We have strategically positioned ourselves to support our clients by delivering innovative and efficient solutions tailored to their project needs. Maintaining and strengthening these relationships remains a priority, as we continue to share our expertise and project insights to drive operational efficiencies and deliver the highest standards of service across the industry”.

As the energy sector navigates increasing complexity and operational demands, STATS Group continues to pioneer advancements in subsea pipeline technology. Its engineered solutions not only address current industry challenges but also set new benchmarks for safety, efficiency and sustainability in offshore operations. With a proven track record and a commitment to excellence, STATS is poised to lead the next wave of subsea infrastructure development.

© Supplied by STATS Group

© Supplied by STATS Group © Supplied by STATS

© Supplied by STATS