With the focus of the oil and gas industry on Aberdeen as the city welcomes Offshore Europe 2019 to new venue P&J Live, the global engineering, manufacturing, rental and service company ACE Winches is looking forward to exhibiting in the Scotland Pavilion.

Since the last Offshore Europe, in 2017, there has been a welcome upturn in activity in the North Sea. However, the industry continues to be unpredictable, putting pressure on the supply chain to provide value and efficiency.

There is a focus on increased support for clients to maximise operational efficiency, safety and capability, reducing equipment stoppage and loss of operation.

An economical solution for platform FPSO and drilling rig operators is to refurbish and upgrade existing assets.

The experienced and qualified inspection teams at ACE Winches provide expertise to carry out assets’ five-yearly IACS Special Periodical Survey (SPS) in line with relevant requirements.

ACE Engineering and Services

The company provides full packages for servicing existing assets, for ACE equipment or for other equipment provided by a third party.

This includes complete overhauls, product upgrades, FMECA and engineering surveys, hydraulic servicing and equipment repairs. Master service agreements and service contracts are also available.

ACE Winches recently increased its global presence by expanding its service offering at several strategic locations, including Singapore, Houston, Dubai and Rotterdam, as well as providing services from its bases in Aberdeenshire and Stavanger.

Global support is available 24/7 through its teams of technicians.

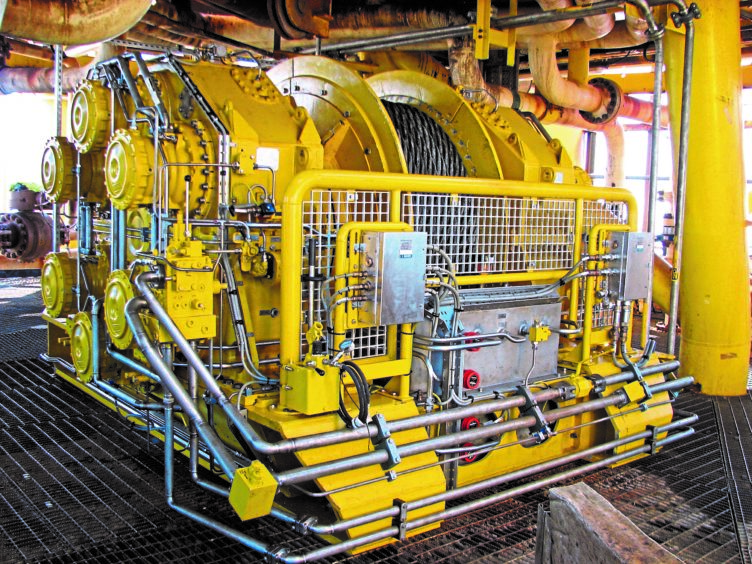

Turret Winch Upgrade

Following an inspection and survey of the components, Petrofac awarded a contract to ACE Winches to rebuild a turret winch aboard an FSU vessel.

The vessel is located off the coast of Aberdeen in the North Sea. Crude oil is deposited from the stern of the FSU to a shuttle tanker, and then carried to refineries in Europe.

ACE Winches was required to procure, fabricate and refurbish the necessary replacement components and subsequently reassemble the winch for operation. The load monitoring system was also upgraded.

Where possible, components were removed from the vessel to be refurbished at the ACE Winches facilities in Aberdeenshire; however, due to limited crane capacity and access constraints within the FSU turret and surrounding deck area, the main structure of the winch could not be removed and work to this structure had to be conducted onboard the vessel.

Once all the refurbished and replaced parts were installed, ACE Winches tested and commissioned the winch to ensure its continued safe operation.

Recommended for you