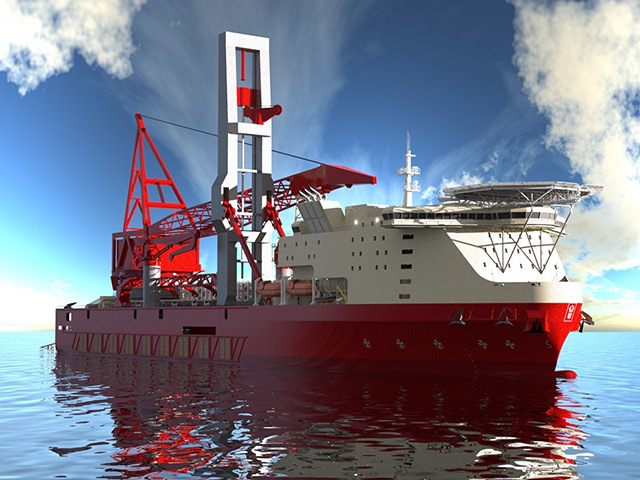

Sharjah-based contractor Petrofac has taken many in the offshore industry by surprise with its decision to step into the deepwater projects market by ordering a sophisticated construction ship.

The company, which has a large Aberdeen and North Sea footprint, says the decision builds on its “market-leading” engineering, procurement and construction (EPC), project management and engineering capability.

The scale of the investment has not yet been revealed; however, it will cost the thick end of $1billion to build, equip and commission.

The vessel will reflect the trend towards integrating J-Lay, S-Lay pipelay capabilities into the same hull.

It is expected to open the door to Petrofac competing for high-end turnkey opportunities in the high growth deepwater and SURF (subsea, umbilical, riser and flowline) markets, and expand access to shallow water EPCI (engineering, procurement, construction and installation) projects.

The Petrofac JSD 6000 deepwater derrick lay vessel is a customised variant of Norwegian group Ulstein’s SOC 5000 design, which was developed by Ulstein Sea of Solutions based in Rotterdam.

The first example of the class is Subsea 7’s flagship Seven Borealis. This was based on an existing hull and cost around $460million.

The second and most recent variant is the Aegir, which was delivered to Heerema Marine Contractors last year at an estimated cost of $600-700million.

While there is to be a significant European equipment and systems content, the Petrofac vessel will be built in China by ZPMC. Delivery is scheduled for early 2017.

Key contract awards to date include:

- Nominated supplier and integrator of all electrical and control systems: Kongsberg Maritime, Norway

- 2,000 tonnes J-Lay tower: IHC Engineering Business, UK

- 5,000t revolving main crane and four deck cranes: National Oilwell Varco in the US

- Two deepwater 750t winches: Remazel Engineering, Italy

- 600t S-lay tensioners and pipe handling equipment: Remacut, Italy

- Nominated classification society: Lloyds Register

At the operational heart of the Petrofac ship will be a 600t Remacut S-lay system via a centre firing line below main deck, and a 2,000t IHC EB J-Lay system via a moonpool.

This double deck configuration, a distinctive feature in Ulstein Sea of Solutions designs, allows for a large, unobstructed deck area and below deck pipe fabrication.

A delighted Edwin van Leeuwen, managing director at Ulstein Sea of Solutions, said: “We feel it is a recognition of our design capabilities for this high-end market.

“It is the third customised version of our successful ULSTEIN SOC 5000 design after the ‘Seven Borealis’ and ‘Aegir’, which are both already in operation.

“The success of the project comes on account of the close cooperation between Petrofac’s team and our project team, managed by Sjaak Jan Jiskoot.”

The ship’s vital statistics will be:

Main dimensions:

- Length overall – 215.9m

- Breadth moulded – 49.0m

- Depth (main deck) – 22.4m

- Deck strength – 15tonnes per sq.m

- Operating draught – 10.9m

- Service speed – 12 knots

- Installed power 6 x 8.5MW – power station arrangement

- Positioning DP3

- 8-point mooring

- Complement 399 persons

The Petrofac vessel will bring a formidable additional capability to the global deepwater construction fleet. Both Aegir and Seven Borealis are regarded as game changers among the current mono-hulls offering.