Decommissioning …it’s one of the hottest topics of the day in the North Sea despite there being many billions more barrels equivalent of oil & gas resources still to chase.

There has, of course, been a huge amount of talk about decom becoming the next big thing for the supply chain resident here in the UK, and indeed some companies are turning a useful crust, not least engineering houses working with operators on a growing list of infrastructure removals and in-situ abandonments.

Given the anticipated decom hit on the public purse, there is huge sensitivity regarding where exactly the contracts are placed and, given the Brexit mess, I can’t help but think corporate xenophobia might rear its ugly head somewhere.

However, there’s no escaping the dangerous fact that far too much of the UKCS supply chain is in foreign hands …a concern that I have commented on time and again along the 15 years of Energy’s existence and a decade of Offshore Journal prior to that. That will impact decom, in my view.

This includes sophisticated engineering capabilities which have long been considered a UK strength, but which are also largely under foreign ownership. Notable exceptions of course are Amec Foster-Wheeler and Wood Group.

It has been pointed out to me that so much of the value locked up in decom lies in the preparation of late-life fields for their coup de grace, ergo the engineering, rather than actual removal of platforms and so-forth.

But say the managing contract for shutting down and removal of all infrastructure from the Tattie Bogle field is placed with a major subsea contractor then, with the exception of true blue Bibby, de facto the real beneficiaries are foreign corporations, mostly Dutch, French, Italian, Norwegian and Swiss, who not only have excellent global engineering capabilities but, critically, also own the hardware, oh and toolboxes with which to cream the high visibility work – actual lifting and removal of the heavy metal.

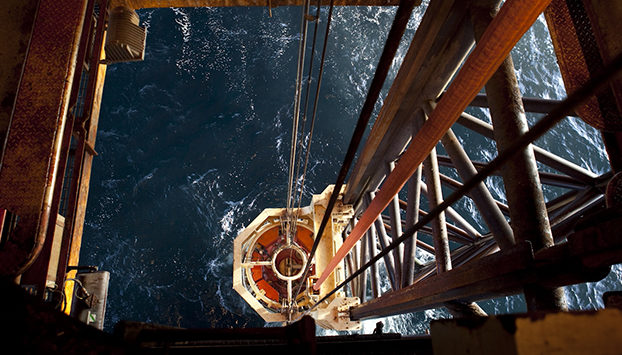

One of the bread and butter parts of decom is final plugging & abandonment of wells of all sorts, with the tally already past the 5,000 mark and another 6-7,000 or so to go, including the 2,000 or thereabouts forecast for drilling on the UKCS between now and whenever.

What gets me about this aspect of offshore decom is that, as far as I’m aware, the physical side is entirely in foreign hands. There are no British-owned ships playing in this space. And as UK companies also don’t own any mobile offshore drilling units, except for perhaps a handful of barges/jack-ups in foreign climes, that’s that.

Or is it?

I recently paid a visit to a senior figure in the Aberdeen-based drilling community for a catch-up. This was at the height of the Transocean Winner affair when it was touch and go as to whether the rig would get off the west side of Lewis rocks it was impaled on.

Needless to say, this rig attracted comments, including that it was more seriously damaged than had been revealed. It seems that the Winner came close to grief several times after being dragged off the rocks and towed to a safe haven in Broad Bay, pending it being picked up by the heavy-lifter Hawk …not British, I hasten to add, as we don’t own any of those either.

It seems that the bottom plating of its pontoon hulls were more severely damaged than initially thought. The only barrier between staying upright and rolling over and descending to Davy Jones’ Locker was the vast amount of compressed air being pumped into the pontoons.

I was told that there was video footage doing the rounds in Aberdeen that showed the rig “wobbling” …listing one way then the other …while under tow. Be that as it may, eventually the Hawk uplifted the Winner and headed off to the Med last month for breaking up.

This rig, like so many others, was a casualty of the current downturn, with Transocean setting the pace in terms of disposals of mostly old semi-submersibles, including North Sea-capable, for scrapping.

I need hardly remind any of you that there is a serious need to drive down the cost of decommissioning North Sea infrastructure and, should there be a significant turnaround in the oil price near-to-medium term (say one to three years), there is an acknowledged risk that even this market could overheat.

With a vast number of offshore-related jobs shed worldwide, there is less expertise on-tap today than two years ago … and so-on, and so-on. I’m sure you get the picture.

Given that well P&A is the largest component of the overall UKCS decom bill …almost half …the cost involved is huge. It is also hard to commoditise as every well is different. That said, there is a growing list of examples where significant time and cost savings have been made on field wells abandonment campaigns.

Given that many more drilling mobiles are destined for the scrapper, I’m wondering if there is any value in considering setting up a UK-owned wells decom company with enough money in the pot to buy up a trio or so of perhaps more or less sister rigs (semi-submersibles with DP) that are in-ticket for the UKCS, or can be brought back to the required spec at modest cost, and then dedicate them to well P&A work?

Despite the success of companies like Helix – especially – with monohulls, there is clearly a need for rigs, which are traditionally more expensive to hire for such work, even now.

But what if that cost gap could be closed by a company (or companies) working with rigs recycled back into the market at a small premium over scrap value, purely for well P&A, perhaps working on block contracts awarded by coalitions of operators (or area operators should the concept gain traction)?

Years ago, I suggested a North Sea operator model where a major mimics the airlines and sets up a budget operation to cater for late-life production of fields that would otherwise be sold off.

Might this be possible for well P&A? I can’t help but think there’s the grain of something feasible and profitable in this. My drilling mentor thinks so.

Recommended for you