Through all the buzzwords and jargon, we all recognise the value that the widespread adoption and effective application of digital technology will have in the upstream oil and gas sector.

It will make our industry leaner, greener, safer and more efficient.

I’m excited by the potential of technology to more effectively recover hydrocarbons – leaving unwanted fluids in the ground, increasing operating efficiencies, and reducing the number of wells required.

To do this, the systems we deploy must include components within the wellbore, providing data, communications and control. For this to work effectively we may need to change the way we think about the wells themselves.

We often cite examples of consumer electronics to provide an illustration of the pace of technology development.

If we look back 15 years, not excessive for a well life, we would have iPods not smart phones, modems not broadband, and CRTs (Google it), not LCD

TVs.

While it’s fun to amuse young people with tales of life before smart phones and

Wikipedia, the fundamental difference is that once obsolete, we simply throw these devices away and get a new one. A luxury we don’t have in our industry.

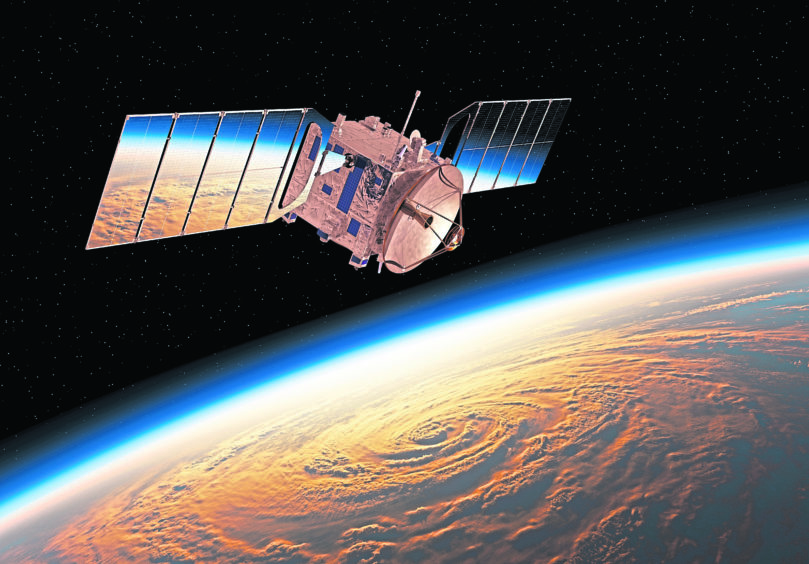

A more relevant analogy may be found further down the digital chain, in the world of satellite systems. The geosynchronous orbit satellites used in telecommunications have a typical working life of 15 years with a high initial capital cost of around

$50 million for the satellite and a launch cost of $50-400 million. Do you see where I’m going here?

The satellite industry is rapidly changing with advancements in computing technology.

This is enabling significant downsizing for cost reduction and distributed system capability, the introduction of flexible, deterministic software for more efficient operations and increasing functionality. These advances are leading to a rapid growth in deployment that looks set to change our ability to explore space and communicate across the globe.

However, the industry is also focused on managing and supporting its legacy systems. There are reports of heritage components being brought back into manufacture to support these systems with the associated challenges of their reintroduction, and of personnel being brought out of retirement as key competencies are lost.

It is lifetime limits of the satellites themselves that drive the capital expenditure cycles of satellite operators. The Holy Grail for operators of these legacy systems is to be able to refuel, repair and replace components in orbit to extend the satellite’s life. Trials are currently ongoing with robotic repair systems and drone technology development to allow just that.

If we now draw parallels between satellites and well technology, system cost reductions with distributed system capability, more efficient operations and increased functionality are also key to digital technology achieving its potential in reservoir management. But perhaps our Holy Grail would instead be well technology that can readily interface with new or legacy systems, that can be simply replaced if damaged, at the end of its service life, or simply to

be upgraded.

We are working towards this in today’s technology developments. We must, however, also change the way we think about wells from an initial capital expense to a dynamic environment which can be adapted to the rapid changes our industry will undergo over the next decade or so.

Annabel Green is chief technology officer at Tendeka