Wind farms today are not generating the power indicated by energy yield assessments. A significant body of industry research is pointing to pre-construction energy yield assessments (EYAs) being overestimated, when compared to the turbines in operation onsite. One paper shows that European EYA assessments overestimate yield by an average of 8.9%.

In Europe, many test sites are selected near coastal regions: high-speed wind locations where the wind tends to blow straight off the sea, in good, stable test conditions. These test sites have relatively low proportions of low wind speed, which minimises load testing and power-curve testing durations for new designs.

Once you take a commercial wind turbine out of these conditions, it is likely to perform differently. Wind measurement campaigns confirm an increase in turbulence intensity at low wind speeds. At lower wind speeds, the wind simply does not blow perpendicular to the measured average wind direction as much of the time within any 10-minute measurement period. The distribution of wind direction about the average varies from site to site and always increases at lower wind speeds. This results in a lower wind resource perpendicular to the rotor disc than the wind speed measured by an anemometer would suggest.

Even wind resource overestimation by as little as a tenth of a meter per second can have a significant impact on energy yield estimates; and at lower average wind speeds, the impact becomes vastly more significant. Overestimating wind resource by just 0.2 meters per second will impact yield by 8% at average wind speeds of 6m/s, but only by 4% at speeds of 8.5m/s. Based on my analysis, energy yield assessments are overstated by an average of 0.3m/s across Europe, which has major implications on low wind speed sites.

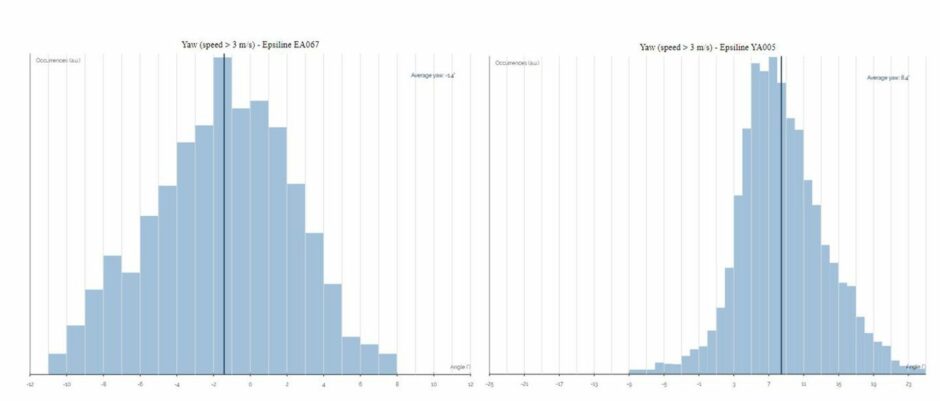

Can any of this lost yield can be recovered? NTR recently completed a pilot project on wind farms in France, Italy, UK and Ireland using LiDAR (Light Detection and Ranging) technology which accurately measures wind speed and direction. What we confirmed is that only a proportion of “10 minute” wind bins are aligned to the wind turbine direction, with significant site to site variation. This can be due to wind turbine yaw control capability and site wind directionality conditions. The two plots below – 10-minute average direction, relative to nacelle direction – indicate how different distributions can be.

What we have found, is that each 10-minute wind bin has its own internal wind direction distribution which is worse at lower average wind speeds. Moreover, the 10-minute data is distributed around an “average” direction relative to the wind turbine. It’s plausible to assert that these two factors are important in explaining current EYA overestimation.

But there is some good news. On testing completed to date, NTR found static yaw misalignment on 95% of its turbines supplied by three different manufacturers. By relatively simple reconfiguration of the turbine software, they could be adjusted to point more directly and consistently into the wind. We are rolling out LiDAR analysis and reconfiguration across all our European projects and anticipate a yield improvement of at least 1% across our portfolio.

There are other benefits to these adjustments – initial analysis indicates that by aligning the turbines better into the wind, we are reducing the loads on the towers, blades and foundations, thereby extending the life of these assets.

The winds of change are blowing across the European energy landscape. Wind power currently making up 17% of Europe’s electricity mix, but the REPowerEU plan aims to expand Europe’s renewables in electricity to 69% by 2027. This target is unlikely to be met. The IEA estimates that only 55% renewables will be achieved in a best-case scenario.

There is a shortfall to be made up – and wind energy can play a part here. As an industry we need to challenge our most basic assumptions about wind turbine performance. Only by rethinking our entrenched calculations can we make the most of this sustainable resource.

Joe Dalton is Asset Management Director for NTR. A veteran of Power Generation since 1987, he has been involved in the development, construction and asset management of over 6GW of wind across multiple markets.

Recommended for you

© Supplied by NTR

© Supplied by NTR