Many of the electronic tablets equipped with software for offshore inspection work in the last few years were ineffective, according to a boss at energy service firm Oceaneering.

Amid the rush to get tablets out on the market, Oceaneering opted to press pause and come up with a product that could really move the needle.

Thomas Aas Saethre, the firm’s vice-president of integrity management, said the decision to delay was “tough” in the face of pressure, both internal and external, to get technology into the hands of offshore workers.

However, Mr Saethre saw sense in the approach: “We took the view a couple of years ago, back when everyone had the fever about getting tablets out, that if you are only going to convert what you’re doing on paper onto a tablet, then the efficiency gain will not be that big.”

He said a lot of “tech effort” had been wasted by competitors, who had achieved nothing more than an “immature showcasing” of some devices that “did not add the efficiency they wanted”.

Oceaneering has now unveiled its own attempt at tablet-based inspection, which it claims can provide productivity gains of 30%.

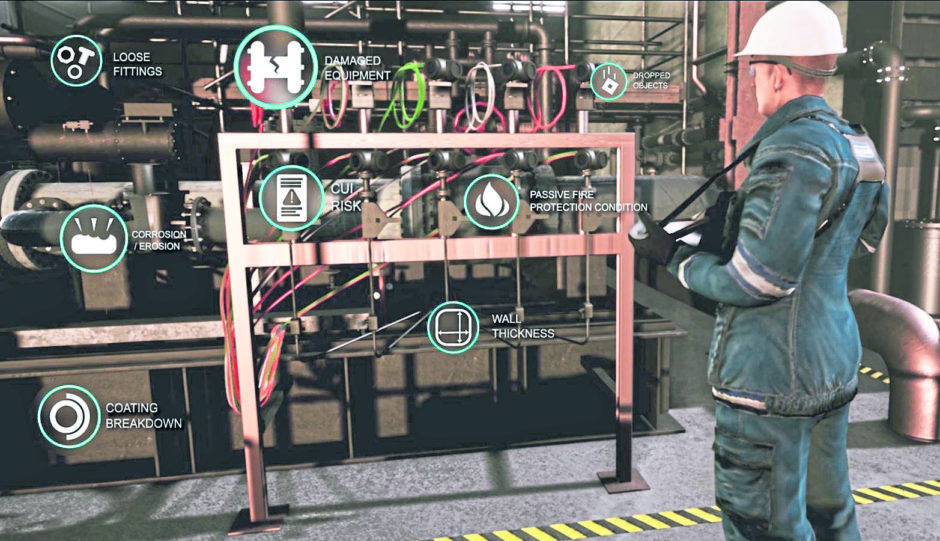

Oceaneering’s Inform Inspect digital asset inspection system has been designed to streamline non-destructive testing (NDT) and inspection management.

It gathers and stores standardised data in a cloud-based system, which makes information instantly available for analysis.

That, in turn, leads to better planning and use of manpower.

The hardware – the tablet itself – is rated for onshore and offshore applications and can be used in hazardous areas, though the speed with which the product can be used means workers will spend less time in dangerous environments.

Mr Saethre said the tablet was not the main cog in Inform Inspect – it’s just the device needed to collect the data – it’s the software that really improves the workflow for clients.

He said: “We’ve given our clients and inspectors a tailored system for inspection. It comes out of the box and can be used from day one. It requires very little setup time.

“We’ve standardised the way data is collected.”

Bill Boyle, senior vice-president for asset integrity, said the technology “transformed” approaches to planning and measuring inspection efficiencies.

Mr Boyle said Oceaneering already had an “agreement” in place with a global oil and gas operator for use of the system, adding: “Our customers can compile, execute and review work scopes in real-time, significantly reducing end-to-end inspection turnaround.

“Our technology is market-leading, field-proven and provides the only global, integrated approach for inspection management to deliver inherent cost efficiencies and safety benefits.”

Recommended for you