On April 4, the base plates were laid for Fugro Seacore and Van Oord’s large walking jack-up barge WaveWalker.

Business managers Jelle Mens and Les Lugg of appropriately-named Wavewalker BV presided over the ceremony at the Neptune Shipyard in Hardinxveld-Giessendam, The Netherlands.

The symbolic “keel-laying” is the first milestone in the construction process.

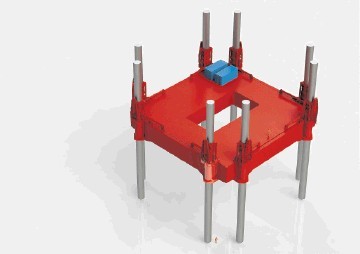

The innovative and large WaveWalker 1, is being developed by Fugro and Van Oord to move and operate in rough seas, surf zones, beaches and other intertidal locations.

Basic characteristics:

Size: 32m x 32m x 4.5m

Moon pool: 17m x 9m with full cover if required

Payload: 400 tons

Marine construction crane: 100 tons @ 6.5m radius

Assisting crane: 10 tons at 20m

Eight legs: 1.80m x 40m long

A 50:50 joint venture company, WaveWalker BV, is being registered in The Netherlands and the two companies are working together on the design, construction and operation of the jack-up which is expected to be ready for work late this year.

Its first job will be on drilling and blasting works for the new Brazilian Suape outer channel, a contract recently won by Van Oord.

“Lugg said: “WaveWalker is an innovative jack-up that can be operated in conventional 4-legged mode, or as an 8-legged, self-contained walking jack-up platform, capable of safely operating and bi-directional movement whilst elevated.

“This will bring great market advantages when undertaking geotechnical site investigations, drilling, trenching, pipeline and cable laying, blasting and other underwater work.”

Mens, who is also a general manager at Van Oord’s said it was expected that WaveWalker 1 will boost the productivity of a variety of the company’s traditional barge and jack-up operations.

“We can now undertake our drilling and blasting works from a stable platform with the added benefit of relocation without floating,” said Mens. “This reduces the impact of sea conditions on the operational hours required for the anticipated drill and blast operations in Brazil.”

The development of the walking jack-up concept has been thoroughly tested over 14 years by Fugro Seacore in heavy seas, surf and high winds.

The concept has been successfully used in activities such as installing pipelines through surf zones, excavating trenches, geotechnical drilling and drilling and blasting in areas where floating equipment or conventional jack-ups would experience extensive delays due to weather down-time.

It also offers safety advantages over operating floating equipment in nearshore, large swell locations.