In contrast to Johan Sverdrup, which is located in a mature area of the NCS, Aasta Hansteen opens up the deepwater frontier of the Norwegian Sea.

Total recoverable reserves for Aasta Hansteen, previously called Luva, are preliminarily estimated at about 47billion cu.m of natural gas and 800million cu.m of condensate.

The investment decision is expected in late 2012/early 2013, with production start-up at the end of 2016. Aasta Hansteen field will be run from Harstad, Statoil’s new operational base in the north of Norway.

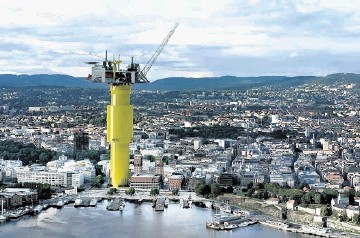

This will be the first European project to make use of production spar technology; moreover, it will be the largest ever built.

Whilst Technip owns the intellectual property for this type of platform and most hulls have been built at the company’s Pori yard in Finland, the Aasta Hansteen spar will be built in the Far East.

Last month, Statoil awarded Technip a letter of intent for construction of the hull, which will be carried out in consortium with Hyundai Heavy Industries (HHI).

Contract value is some $655million. Part of the spar work will begin this month, with completion of deliveries set for the middle of December 2015.

“The hull contract is an important first construction step for the Aasta Hansteen field development,” says Ivar Aasheim, Statoil’s senior vice president for field development on the NCS.

“Aasta Hansteen is the start of deepwater development in the Norwegian Sea and the development could also open up for tie-backs to other discoveries in the same area.”

The platform will be the first Spar with storage capacity and will be able to store about 25,000cu.m of condensate, and export gas via the Norwegian Sea Gas Infrastructure (NSGI).

Once built, it will be transported on the world’s largest heavy-lift carrier, the order for which has been placed by owner-to-be, Dockwise.

Technip will design, procure and deliver the Spar platform hull readied for mating with the platform topsides in Norway. The supplier will also design and prepare specifications for steel rigid risers and a complete mooring system.

“We’ve had several early-phase and concept studies for the entire Aasta Hansteen project, with Technip, Aker, Samsung, FMC, Saipem and IKM, among others, involved in developing the concept,” says Anders Opedal, senior vice president for projects in Statoil.

“The hull is the first execution contract to be set and we are satisfied that Technip has the necessary capacity to take on this assignment following strong competition with other players.”

In May, Statoil arranged a supplier seminar in Bodø in cooperation with the PetroArctic supplier network. More than 100 people from 60 small and medium-sized local companies were given information there about the Aasta Hansteen project.

Statoil has ambitions to create big spin-offs and is charting opportunities for competitive deliveries from the north-Norwegian community and other bidders in the supplies industry at the earliest possible stage of the project. This is in line with Norwegian government policy which seeks to maximise local content wherever possible.

“In the course of this autumn and next spring we’re going to award contracts for topsides, subsea facilities, pipelines, marine operations and drilling,” says Opedal. “There’ll be opportunities for qualified sub-contractors and our ambition is that the Aasta Hansteen field will make a contribution to industrial development in northern Norway.”