Fugro Subsea Services Ltd, based in Aberdeen, has successfully completed the mobilisation of five FCV 3000C work-class ROV systems.

These brand new ROV systems were installed onboard four support vessels; two existing ships in the Fugro Subsea Services fleet had their ROV capability upgraded, while two new ROV support vessels have been added for 2013.

This significant enhancement to the overall capability has been introduced to support a wide range of client projects in North West Europe and West Africa. As well as the investment in ROVs and vessels, Fugro is also adding a further 80 personnel to its offshore and onshore support teams.

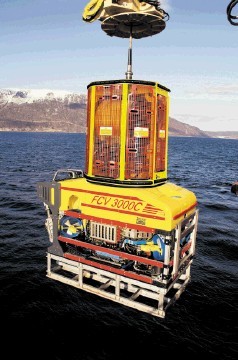

The FCV 3000C is Fugro’s latest generation of high horsepower, deep water ROV capability and is part of a family of remote technology solutions designed and built in-house at the Fugro Subsea Technologies facility in Singapore.

Globally, Fugro now operates a total of over 150 ROV systems with 55 of these being FCV derivatives, ranging from the FCV 600D through the FCV 1000C and FCV 2000D all the way to the FCV 3000C.

In addition to providing Fugro with the latest technologies to implement into their ROV Systems, the FCV programme has also provided spin-off benefits to other Fugro divisions that operate underwater machines, such as the Geotechnical Division where a number of their deep-water coring machines have recently been upgraded using FCV control and mechanical components.

A key feature of the FCV 3000C is the full simulator capability built-in to the topside control console.

When combined with the engineering simulator that is an integral feature of the subsea engineering team’s capabilities in the Aberdeen and Perth (WA) offices, it is possible to fully engineer a solution in the onshore simulator and then send that to the offshore teams who can load the scenarios to their FCV console and undertake mission rehearsal and/or pilot familiarisation ahead of conducting the actual task for real.

Alternatively, during vessel transits or other quiet periods of operation, the offshore simulator within the console can be used to hone pilot skills and even allow the ROV Supervisor to assess competence in conjunction with standard scenarios and test areas developed by the Fugro Academy.

As part of its ongoing strategy of maintaining one of the youngest ROV fleets in the world Fugro has this year, already replaced five of its older systems and by the end of the 2013 programme, this figure for replacements will total 10 in the Aberdeen-based fleet alone.

Skandi Carla upgrade

The first, and possibly the most challenging, upgrade took place on the ROV support vessel Skandi Carla.

Challenging, especially as the spread already has a full work schedule for 2013 supporting major installation projects in the North Sea and the decision to, not only replace the existing ROV systems, but also to fully upgrade the survey and processing areas of the vessel meant that the ship had to be out of operation for the period of the upgrade.

No overrun of this phase could be allowed as the vessel and equipment spreads had to be fully tested and back in service to undertake client commitments.

The upgrade work involved replacing both ROV launch and recovery systems (LARS). This included the installation of a new, active heave compensated, moon-pool launched ROV and an over-the-side “A” Frame launched ROV.

At the same time, the ROV control stations and the on-line survey suites were combined into a single open plan area, providing easier ROV and survey crew communications.

The operation was meticulously planned during 2012 and successfully completed in March, with the vessel sailing to its first project immediately thereafter – on time.

Initial feedback from the field staff, who were involved at all stages of the planning process, is that the upgrade and modifications have been very well received and that they provide a much improved working environment onboard.

Inspection vessels

To support its oil and gas inspection projects, undertaken by the IRM business line, Fugro Subsea Services has chartered two further vessels.

The first of these; the 2003 built Grampian Surveyor from Aberdeen-based Craig Group was outfitted with another, new-build, FCV 3000C system along with two Seaeye Lynx vehicles.

The vessel is specified with the latest HD (high definition) video technology and a 24Gb data highway to facilitate both HD video and multiple sensor recording and distribution of all inspection operations. All control systems are built into the vessel, with the FCV and survey teams located together in one spacious control room, while both Lynx systems are located in adjacent rooms.

All ROV systems are mounted on a purpose-built, elevated mezzanine deck leaving a large area of the ship’s back deck available for specific project equipment, which is accessible by the ship’s 20-tonne capacity crane. Already the Grampian Surveyor has successfully completed several projects and has a busy programme planned for both this year and next.

Within the next 12 months, operational projects will be undertaken in the UK, Danish and Norwegian sectors of the North Sea and further afield in the Mediterranean and several West African countries.

The second vessel is the 2012-built Olympic Commander, an MT6015 design, owned and crewed by Olympic Shipping AS of Norway. The Olympic Commander is fitted with a similar ROV spread to that described above for the Grampian Surveyor, that is, 1 x FCV 3000C and 2 x Lynx systems, all arranged for over-the-side deployment.

These two vessels have now joined our existing IRM vessel the Skandi Olympia, which was also upgraded with a new-build FCV 3000C vehicle and collectively they provide Fugro Subsea Services with three versatile ROV support vessels to service all of its clients’ IRM needs.

Old systems not going to waste

Keen to prove that old ROV systems never actually go away and to make sure that the technology, even if some of it may soon be obsolete, doesn’t go to waste, Fugro have offered up to three of the demobilised ROV systems to the Underwater Training Centre (UTC) at Fort William under a long-term loan arrangement.

Planning is now under way to transport the ROV systems to Fort William and install them at this world-leading training facility so as to offer additional courses that can provide a more operational element. These new courses are being developed in conjunction with the IMCA ROV Division Management Committee, with input from the well-established Fugro Academy.

Fugro and UTC already have a long history of collaboration and working together; Fugro previously donated a Scorpio ROV System to the Centre and FSSL has put over 200 trainees through our own (Fugro) ROV induction course in the past seven years, which includes the trainees spending part of their induction at the Underwater Centre.

All of the technical and operational training undertaken within the Fugro Subsea Services Division is run under the auspices of the Fugro Academy, which includes a dedicated ROV Faculty, complete with its own principal and trainers.

The Fugro Academy assists the operating companies to implement personnel competence schemes and is also responsible for controlling the delivery of training provided at the different locations around the Fugro world where the onshore training Simulators are based.

These onshore training Simulators are fully compatible with both the offshore FCV based Simulators and the Engineering Simulators hosted in Aberdeen and Perth WA.