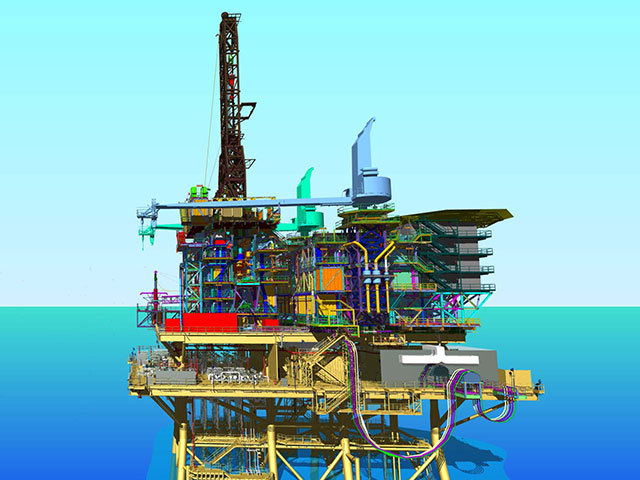

Houston consultancy William Jacob Management Inc. (WJM) has introduced a new modular offshore drilling rig design that it says reduces deployment costs and improves speed-to-market for upstream operations.

The so-called Modular Offshore Rig Facility (MORF) to be rated 3,000bhp is touted as being the first of its kind in size and configuration.

Developed for a national oil company with a major presence in the Gulf of Mexico, WJM says the design was driven by the client’s demand for improved cost performance across its offshore operations.

“Our team of design engineers deliberately downsized the individual modules so they could function like a set of interlocking building blocks and be lifted in-place by ‘leapfrog’ cranes,” says Trevor Smith, VP of drilling facilities engineering.

“This solution enables the modular rig to be configured for drilling and integrated production below, while providing significant cost savings in deployment.”

The rig has two main modules: the drilling equipment set (DES) and the drilling support module (DSM).

The DES has a designed capacity to access 15 wells arranged in a 3 x 5 matrix and will be capable of drilling wells to 7,620m (25,000ft) depth.

The DSM design features a pair of rig cranes that streamline installation and WJM says the modules can be delivered using the client’s service fleet, and then assembled using a combination of crane systems.

The blocks containing the cranes are installed using a temporary “leapfrog” crane package. Once the rig cranes are operational, the installation is then completed using the rig’s own cranes. This strategy eliminates the need to contract a lift barge.

WJM is an independently owned, engineering and project management services firm which claims more than 375 years of collective executive experience.