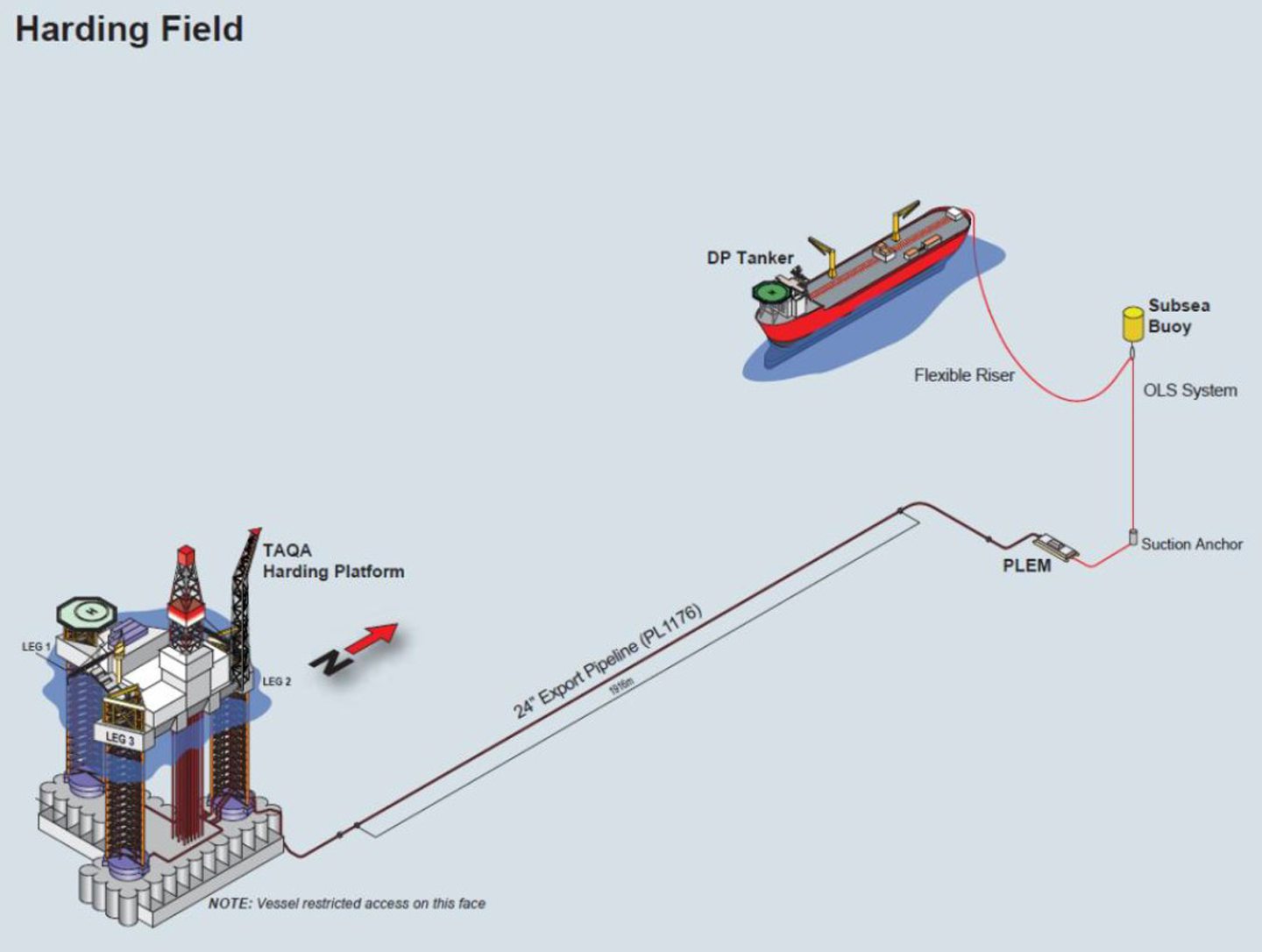

TAQA is looking for a solution to a big challenge in the removal and disposal of its three-legged Harding platform in the North Sea.

Its design means traditional methods of removal for the jack-up – reverse installation (jack-down and sail-away) or alternative removal such as a heavy lift – may not be available.

Both of these options present challenges, as TAQA decommissioning project manager Malcolm McCrombie set out at an OEUK sharefair event last month.

It comes as TAQA expects to dish out the Engineering, Procurement, Removal and Disposal (EPRD) contract for Harding next year.

Jack down?

After construction in Korea, the Harding rig was transported to Norway via a heavy-lift vessel then towed into position, around 200 miles north-east of Aberdeen.

The jack-up was “locked-in” to its upper positioning upon installation in the 1990s and the ballast and jacking system have since been decommissioned.

It means the rig cannot be “jacked-down” and towed away, as might usually be the case, unless the ballast and jacking systems were replaced or reinstated in-situ.

TAQA said the “significant challenges” involving that means the firm wishes to avoid any removal options requiring those systems.

There are also considerable issues linked to the reliability of the hull’s buoyancy. A report produced by TAQA in November said the Hull has only been inspected for support of the topside structures, and therefore has lost its “ship classification” compliance to be towed away.

Single lift?

The rig is also not designed for modular removal – and its triangular shape makes it a challenge for traditional heavy lifters like Heerema and Allseas.

That could mean a requirement for the rig to shed weight and there could be “piecemeal” opportunities for the removal, according to Mr McCrombie.

Last year, decom project director David Wilson described Harding as having a “highly unusual design and configuration, based as it is on a three-legged jack-up rig structure, which makes it challenging to deploy conventional removal techniques”.

Other solutions

The firm has been seeking innovative supply chain solutions to the Harding challenge, with a planned cessation of production date of Q2 2027 currently mooted.

Well abandonment is scheduled to take place from 2025 – 2027, then “de-energisation activities” and disembarking workers from the platfor, is planned for completion by Q2 2028.

The removal window is expected to be no earlier than Q2 2028.

Harding was installed in 1995 with a 35-year design life. TotalEnergies is a 30% project partner.

© Supplied by TAQA

© Supplied by TAQA