© Supplied by Amy Mackie/PA

© Supplied by Amy Mackie/PA A piece of software to optimise subsea decommissioning operations has been developed by Aberdeen’s National Subsea Centre (NSC) and marine AI firm PlanSea.

The new tool aims to slash emissions from operations while giving users cheaper and “resource-efficient” outcomes.

The duo behind the software have said that it will address the challenges facing a sector which is set to see an estimated £21 billion in spending within the UK over the next decade.

The project was funded in part by a grant awarded by the Scottish Funding Council in partnership with Scottish Enterprise.

Jim Cargill, chief executive of PlanSea said: “The NSC and PlanSea have successfully collaborated for many years to utilise AI to optimise marine logistics, and this logical extension of our joint technological capabilities to cover subsea decommissioning evidences a UK centre of excellence in this sector.

“This is another step in our quest to digitalise and optimise offshore operations whilst at the same time reducing costs and emissions.”

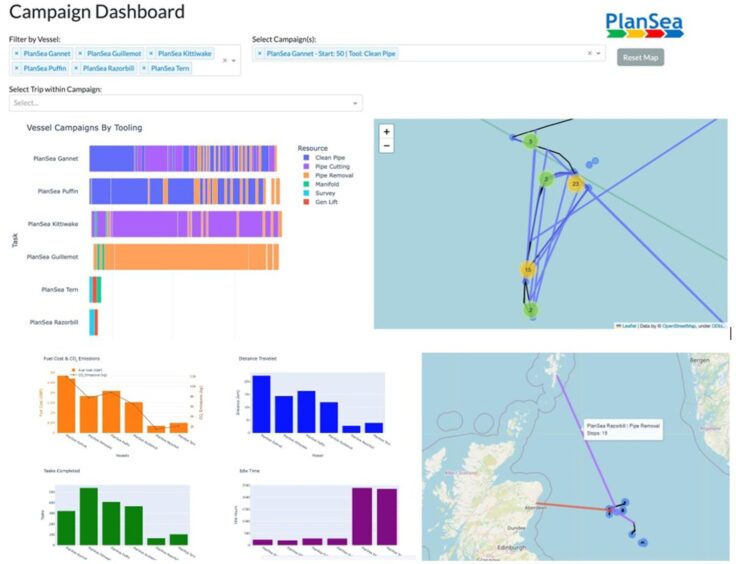

The tech takes in data from private and public sources to produce “task-based activities” which are compatible with current PlanSea visualisation and optimisation software.

It then creates standalone or campaign plans, which show vessel schedules and task allocations. The tool also simulates varying fleet composition and tooling or resource functionality for alternative options for decommissioning plans

Dr. Ciprian Zavoianu, NSC Research programme lead and principal investigator for this project, added: “Together with my NSC colleagues, Dr. Fyvie and Dr. Santos, I’ve had another great experience working with PlanSea on the timely delivery of a challenging piece of marine logistics applied research.

“Dr Fyvie has been instrumental in developing a robust software demonstrator that can ingest decommissioning data from multiple sources and subsequently leverage a bespoke AI-enhanced scheduler to optimise fleet and resource allocation whilst also facilitating the integration of expert insight and feedback regarding operations modelling.”