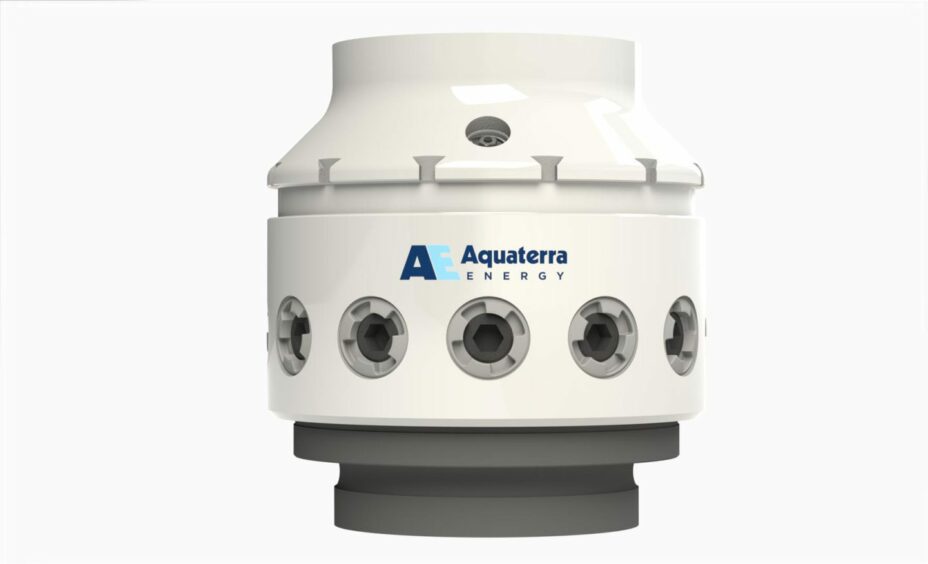

Aquaterra Energy has announced a new addition to its suite of riser and connectors aimed at supporting new carbon capture and storage (CCS) developments.

The firm says its “end-to-end” completions system will allow operators to safely perform workover and intervention operations in low-temperature and high-pressure CCS subsea sites, without fear of gas leakages.

Norwich-based Aquaterra – not to be confused with an Aberdeen-headquartered maintenance group of a similar name – provides equipment and solutions for the offshore energy sector.

Its new patent-pending technology is designed to address the various issues and complexities that can occur when working with stored and pressurised CO2, such as sweet corrosion and ultra-low temperatures which standard carbon steels can’t safely deal with.

Deployable from a jack-up, semi-sub or light-weight intervention vessel, the system is based on the company’s ISO13628-7 completion and workover riser system. This includes its proprietary AQC-CW connectors, which it says can help reduce operational time and ensure system integrity.

Aquaterra Energy innovation director Ben Cannell said: “I’m delighted to be developing yet another CCS solution for the offshore market that will provide confidence and peace of mind to operators. As with our carbon monitoring tool, we are always innovating to provide the essential and most advanced technology that will benefit our customers and support the energy transition.

“Our experience of supporting oil and gas operations allows us to transfer those skills to benefit the CCS market and this solution is a testament to the depth of knowledge and experience our global team has.”

Managing director James Larnder added: “CCS is a critical energy transition technology, expected to scale up rapidly in the run up to 2030, so it’s imperative we continue to advance our solutions for this market.

“We are proud to play our part in supporting these energy transition goals and through intelligent engineering our expert team is always looking at ways to identify what our customers need today and for the future.”

It marks another move into the emergent CCS sector for the firm, which recently launched a CO2 management platform aimed at long-term monitoring and sustained integrity of underwater CCS sites via passive and active seismic arrays.

The company, alongside project partners, is also developing an industrial-scale offshore green hydrogen production concept, deploying an electrolyser system on a converted jack-up rig in the North Sea.

Recommended for you

© Supplied by Aquaterra Energy

© Supplied by Aquaterra Energy