Equinor (OSLO:EQNR) and its Rosebank partners expect to spend around £80 million on modifications to the Knarr FPSO which will ready the vessel to run on low-carbon power.

The Norwegian energy giant submitted an environmental statement (ES) for the 300-million-barrel Rosebank project earlier this month, and outlined plans to invest more than £8 billion over the life of the field.

As operator, Equinor has a 40% stake in the West of Shetland field, while Suncor Energy and Ithaca Energy hold 40% and 20% respectively.

The firm said Rosebank “could become one of the first oil and gas developments west of Shetland to be powered by electricity”.

However it also tempered expectations on the likelihood of a quick floating wind solution.

Knarr

As well as setting out the project’s environmental impact and development strategy, the document provides an overview of how Equinor hopes to lower the operational emissions of the project by adapting the floating production, storage and offload vessel (FPSO) for electrification.

The vessel used – the Altera-owned Knarr, first installed in Norway in 2015 – will be adapted to run on power either from the onshore grid or directly from floating renewables schemes.

The licensees said they intend to invest “around £80 million” on modifications to support the electrification of the FPSO which will be completed prior to the arrival of the FPSO at the field location, according to the submission.

The vessel is a suitable candidate, having already been designed with future electrification in mind, and has available space allocated for electrical equipment in both its mooring turret and on deck.

The necessary modifications listed include the installation of a high voltage slip ring (HVSR) on the turret’s fluid transfer system (FTS swivel); installation of a surge arrestor on the turret to protect the HVSR from potential electrical surge; installation of an electrical house and new transformer on the port side aft of the FPSO; cable routing from the HVSR to the electrical house; the addition of high-voltage electrode boilers on the poop deck to provide the process heat previously supplied by gas turbine exhaust systems.

“All modifications to support the future electrification of the FPSO will be completed prior to the arrival at the field location, without taking the FPSO off station. Further, the FPSO will be equipped with a closed flare and vent system and will be retrofitted with energy efficient equipment,” the statement adds.

Crucially, the FPSO will hold onto its four 13.1MW dual-fuel gas turbines and will be expected to be capable of generating its own power via produced fuel gas prior to a full solution becoming available.

Power struggles

While full electrification of Rosebank is the goal, the strategy for doing so remains under consideration.

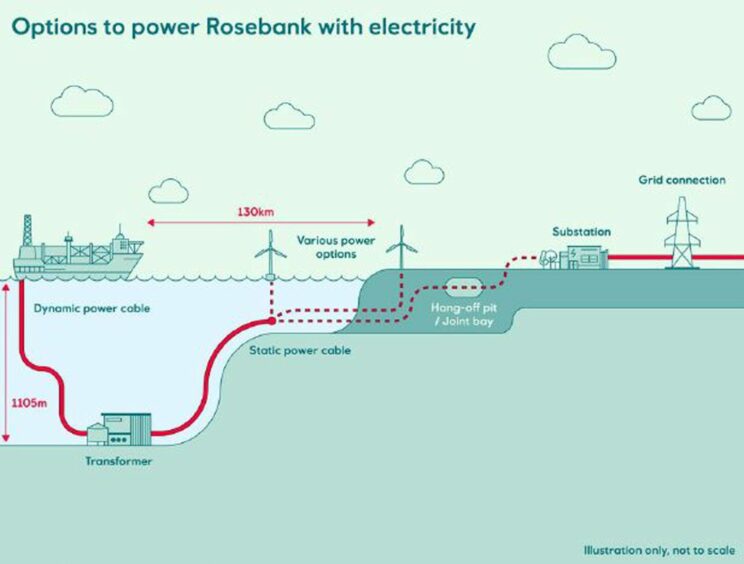

A dedicated floating wind scheme to serve Rosebank has previously been mooted as one potential solution “on the drawing board” and is referenced as a potential route in its formal submission, alongside power from shore via the Shetland Islands.

However, the partners noted that based on experience with existing floating wind farms “having a local wind farm in operation from first oil in 2026 is considered not to be a realistic option.”

Speaking with Energy Voice earlier this month, senior vice president for UK and Ireland offshore at Equinor Arne Gurtner said the operator “has not yet decided on the solution yet, so we are working on that very much now.”

The project partners say they have committed to taking “a proactive role” in delivering electrification “when technology is qualified and matured and necessary regulatory consents are in place,” according to the environmental statement.

They added: “It is not the technical development and implementation of required facilities at the FPSO, but the confirmation of power source, grid connections and necessary offshore and onshore consenting that drive the electrification schedule.”

Running the field on lower carbon electricity is expected to help the lower the carbon intensity of the development to around 3kg CO2 per barrel of oil equivalent (boe) – well below the 2020 UK upstream benchmark of 20kg CO2/boe.

A “base case” model, assuming the use of gas turbines and optimised FPSO operations is estimated to be approximately 12kg CO2/boe.

© Supplied by Equinor

© Supplied by Equinor