The fourth episode of Gigawaters looks to the future, examining how Scotland can make the most of the opportunities presented by floating wind technology.

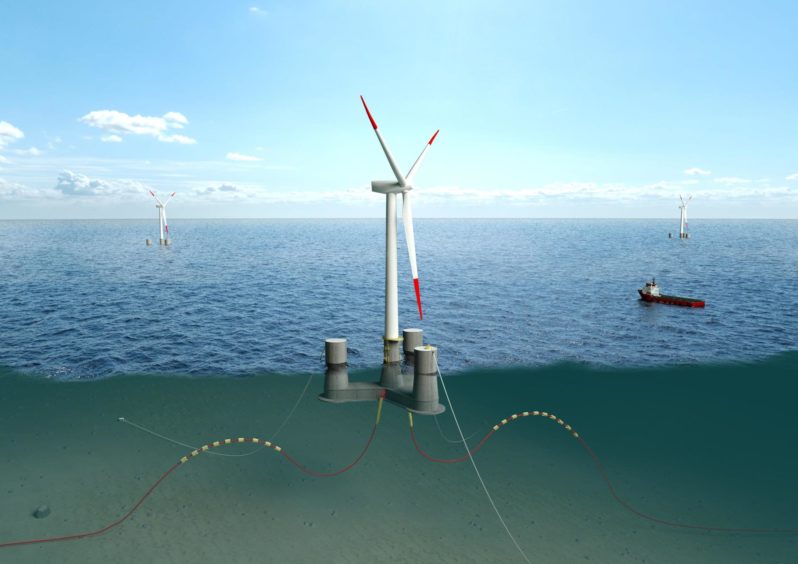

The future, as far as offshore wind goes anyway, will be floating. As deployment ramps up, space that’s suitable for fixed bottom turbines will be at a premium, meaning developers will have to look further out to sea, where wind resources are also greater.

To discuss how Scotland can make the most of this opportunity, Energy Voice’s Hamish Penman was joined by co-host Mairi Dudley, head of market development UK at Ørsted, as well as Carlos Martin, chief executive of BlueFloat Energy, and Joanne Allday, strategic business development manager at Port of Cromarty Firth.

Ms Dudley began by explaining why Ørsted, which has focused largely on fixed-bottom projects thus far, is interested in pioneering floating systems in markets like Scotland and Japan. Though she noted that the technology is in its infancy and the company remains agnostic on which systems to use for each development, Ørsted does believe that it will be commercialised within the next decade.

ScotWind therefore represents “a great opportunity to step into the floating market,” she said. Accordingly, it has entered five bids in the lease round: three Ørsted alone, with a mix of fixed and floating wind technologies, and two floating-only bids as part of a joint venture with Falck Renewables and BlueFloat.

Mr Martin agreed, adding that it was telling and encouraging to see one of the world’s global leaders in offshore wind recognising the potential of the technology and joining forces with a smaller player such as BlueFloat to harness its expertise.

“The opportunity in Scotland is huge, but it’s also a very challenging… We have a new industry to build,” he added. Accordingly, local infrastructure is central to the companies’ bids. He continued: “The applications we have submitted together have a very strong focus on proposing supply-side solutions specific for Scotland that would make those projects viable and cost competitive.”

For ports and the wider supply chain, that’s huge news. Ms Allday said that ScotWind represents “probably the biggest set of infrastructure and construction projects” that Scotland may see in the next few decades, “so the size of the prize is significant.”

Because these technologies are so new, unlike previous fixed-bottom projects where many components were imported, Scotland can build a brand-new supply chain from the ground up, supporting both local content ambitions and future export opportunities, she said, and provide the skilled and sustainable jobs needed to service the sector.

Ms Dudley too pointed to the subsea expertise that already exists in Scotland’s oil and gas sector, which “really does give Scotland a great advantage.”

Moreover, Ms Allday said, given that potential for exporting components and expertise “We shouldn’t underestimate how exciting those jobs are going to be for people coming into the industry… This genuinely is an opportunity to decarbonise the world.

To make that happen, the sector will need political will as much as an eager supply chain. Ms Dudley pointed to “clear and ambitious political target” set by the UK’s 40GW offshore wind target, which includes 1GW of floating capacity. “You [also] need innovation. You need competition,” she said, “but we believe [cost reduction] will happen much more quickly than for fixed-bottom.”

The scale of ScotWind will help that journey, Mr Martin added. As well as the industrialisation of manufacturing and assembly processes, working to gigawatt scales enables improvement far quicker than when working on previous smaller-scale demonstrators – although some medium-term stepping stones, such as the Innovation and Targeted Oil and Gas Decarbonisation (INTOG) project or the Crown Estate’s Celtic Sea rounds will be crucial enablers too.

“Those stepping stones help the industry develop and set the basis for a faster cost reduction,” he added.

At the sharp end of that scale are businesses like Port of Cromarty Firth, who will now focus on how to build processes and facilities to meet demand. Ms Allday pointed to the sheltered port’s near-unlimited weather and tidal windows, allowing faster vessel traffic. The group is also working with contractors to examine the feasibility of extended construction seasons, allowing operations outside of the limited summer windows typically seen at present.

At the same time, floating structures do require need additional space compared with conventional offshore monopiles, both onshore for fabrication and marshalling, and offshore once they are ready for tow-out and installation – something that ports and the supply chain will need to take into account.

Ms Allday also cautioned of the two scenarios which could befall the offshore market. One being the historic cycle seen in offshore wind development where large tracts of land are used intensely for short construction periods, then left. The other is the potential for a major bottleneck to emerge around 2030, as all ScotWind developers aim for the same delivery window – and for which there is not enough infrastructural capacity to meet.

“Neither of those scenarios works for the supply chain, she said. “Neither of them is sustainable, neither gives a constant flow of jobs and projects.” Accordingly, she made the case for a holistic and targeted investment strategy that would allow ports and other infrastructure to be developed strategically and sustainably.

That also leads to a very pragmatic view from ScotWind bidders like Ørsted.

Added Ms Dudley: “I think we have to be very honest with ourselves that the opportunity in Scotland is only going to come to fruition if we can collaborate.”

“That can be challenging because it sometimes means cooperating with competitors, but I think everyone is of the view that the size of the prize is too big for us to work individually on this – and it needs to be done.”

Listen to the Gigawaters podcast by Energy Voice Out Loud.

Recommended for you