Pressure vessels are parts of the offshore plant that help clean produced oil & gas before it is exported to beach for further cleaning.

After cleaning of the crude and gas by the onshore refineries and plants, the oil & gas is provided for use to the general public.

Due to their bigger capacity to hold hazardous oil & gas at elevated pressure, inspection and main-tenance is key to the safe operation of offshore production installations.

The inspection of pressure vessels generally require a platform shutdown to allow internal cleaning of the containers to assist thorough inspection.

A practical alternative to the internal inspection is proposed with the help of a combination of various advanced non-destructive testing (NDT) techniques.

The objective of the use of NII (non-intrusive inspection) technologies on a pressure vessel is to avoid the risk of confined space entry and loss of partial or full production shutdown without compromising the effectiveness of the inspection requirements.

However, the use of a combination of non-intrusive inspection technologies in accordance with DNV-RP-G103 (DNV Recommended Practice G103) is a suitable and in some scenarios, a practical alternative.

Background

NII technologies help detect the material defects which may adversely affect the fitness-for-service capability of a pressure vessel of which there are many offshore aboard production installations.

Wall thickness data of the pressure vessels is obtained using specialist NII scanning which then contributes to statistical analysis and further optimisation of the inspection programme.

NII gives demonstrable compliance with the risk based inspection assessment requirements applicable to the asset.

The whole process can be broken down into 5 distinct steps enumerated below:

• Integrity review (to establish

the relevant damage mechanisms and extent of inspection requirement)

• Assessment review (to establish if NII is possible at all on the pressure vessel)

• Planning process (to deliver a fit-for-purpose NII scope)

• Inspection enactment (to deliver the NII on the pressure vessel)

• Evaluation (to assess if NII delivered the anticipated information to allow sign-off the equipment inspection, or if there are still any further alternative inspection requirements)

What are the NII technologies?

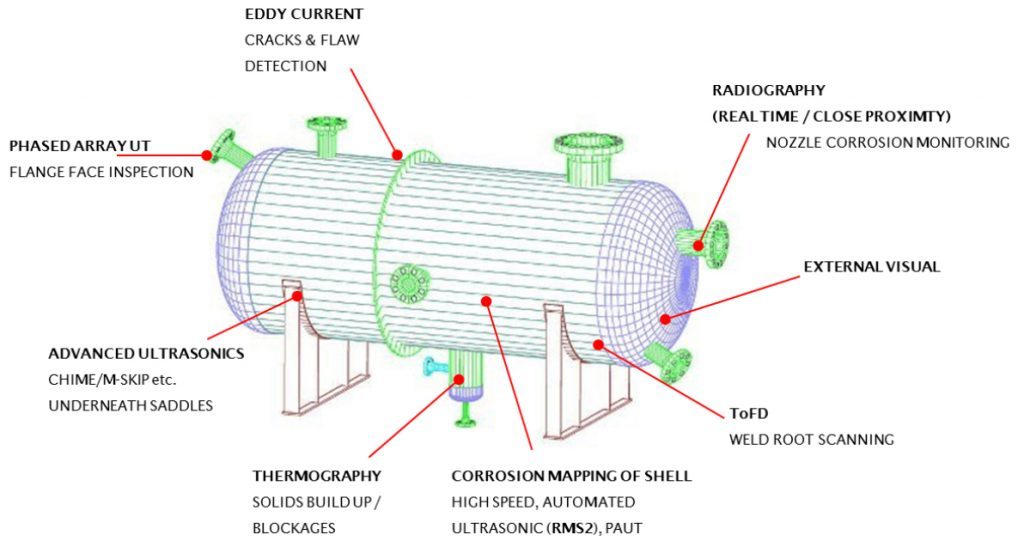

To carryout effective inspection of a pressure vessel an asset integrity engineer has a variety of Non-Destructive measurement tools in at their disposal.

These include:

• Automated ultrasonic corrosion mapping

• Advanced ultrasonic (Chime/ M-Skip)

• Phased array ultrasonic

• Time of flight diffraction

• Eddy current

• Real time radiography

• Thermography