The concept of the circular economy may be new to some, but it has actually been in discussion for some time now.

A notable shift in focus is taking place around the world to minimise waste, pollution and the consumption of finite resources, improve sustainability, reduce environmental impacts and cut carbon emissions. This has led to the concept of the circular economy growing in prominence; a process whereby resources, which are otherwise deemed to be waste, are kept in use for as long as possible by either repurposing them into new products to be utilised in a new way, or by recycling.

Reuse and recycling have been a cornerstone of the John Lawrie Group since being founded in the 1930s. Delivering significant environmental and monetary benefits to our customers during that time has been core to our existence.

We understand the value the circular economy model provides not only to our customers but the communities and environments within which we work, particularly when faced with tightening environmental legislation, establishing zero waste strategies and reducing carbon footprint.

Having identified three decades ago that redundant steel tubulars from the North Sea oil and gas industry could be used as a high-quality replacement for traditional concrete piles, we have progressively developed this area of our business.

Today, at our facilities in Scotland and the United States, our Tubulars division holds a stock of around 100,000 tonnes of steel tubulars that are suitable for reuse in piling and micro-piling projects in the construction and civil engineering sectors globally.

To date, we have supplied over 2 million tonnes of steel tubulars for use as piling for housing, railways, highways and commercial projects, which has minimised waste, saved an equal volume of CO2 emissions and helped establish a more robust economy. Reusing steel casing pipe as steel piling demonstrates the innovative thinking required to fully realise the potential of the circular economy.

Eighty years of experience have enabled us to achieve the highest standards in customer care, health and safety, recycling and reuse, and sustainable environmental services. Over the past three decades we have progressively developed our expertise in finding alternative uses for redundant materials, said Director Iain Laing.

In 2017, our innovation and commitment to reuse and recycling was acknowledged when we won the circular economy award at the VIBES – Scottish Business Environment Awards.

Mr Laing explains how we are working to reuse and recycle materials. He says:

“For a number of years now we’ve been taking tubulars from one industry, oil and gas, and putting them to good use in another, the construction industry, which are two majorly important sectors that fi t into the Scottish Government’s reuse strategy launched in 2016.

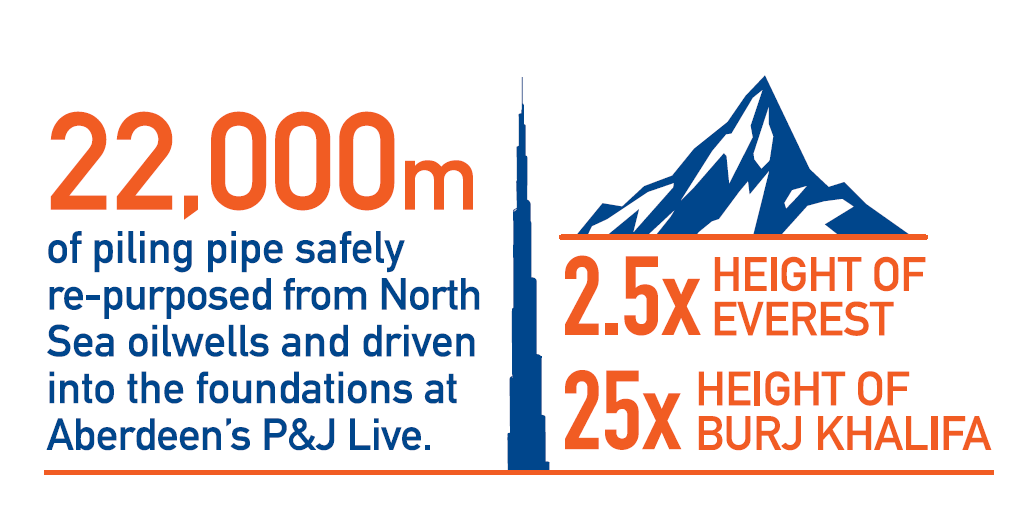

“One of the most recent prominent projects we supplied piling for was the new Aberdeen exhibition centre, P&J Live, where we supplied 22km of steel pipe.

“The energy required to recycle steel is quite high, so by doing what we do we’re eliminating that from the process. For every tonne of steel that is reused there is an environmental saving of up to 0.96 tonnes of CO2.”

The P&J Live Arena, Aberdeen’s new state-of-the-art conference, exhibition and entertainment complex boasts foundations made from 22,000 metres of previously used oil and gas pipe and casing which have been repurposed as foundation piles. We supplied 2,000 tonnes of pipe and casing safely recycled from the oilfield wells of Aberdeen’s major North Sea operators and supply chain companies to the project. Approximately 1,750 piles were installed throughout the six-month project.

In 2010, our group revenue was split 50% recycling and 50% reuse, but today, at the beginning of 2020 our business is now 70% reuse. Our business in America has seen unprecedented growth in reuse, specialising in the supply of piling and more specifically micro-piling mainly in the North Eastern states, but across the country as a whole.

The circular economy is not just good for our business, it’s great for our oil and gas clients whom we’re purchasing from and indeed our construction industry customers who we are supplying to as well. Knowing that the reuse of these products is making a difference to the environment is of great benefit to all parties.

Eliminates waste, supporting zero waste objectives.

Recommended for you