For several years, the aerospace, automotive and other engineering sectors have used concurrent engineering – a mixture of design, analysis, modelling and simulation working together – to provide a product or solution in the most efficient manner. There is now the opportunity to apply similar techniques within the energy sector.

The installation of the cutting-edge marine simulator at the National Decommissioning Centre (NDC) provides the opportunity for the sector to access simulation capabilities which can assist in the development of new technologies and techniques for late life, decommissioning and renewables, helping to de-risk their deployment.

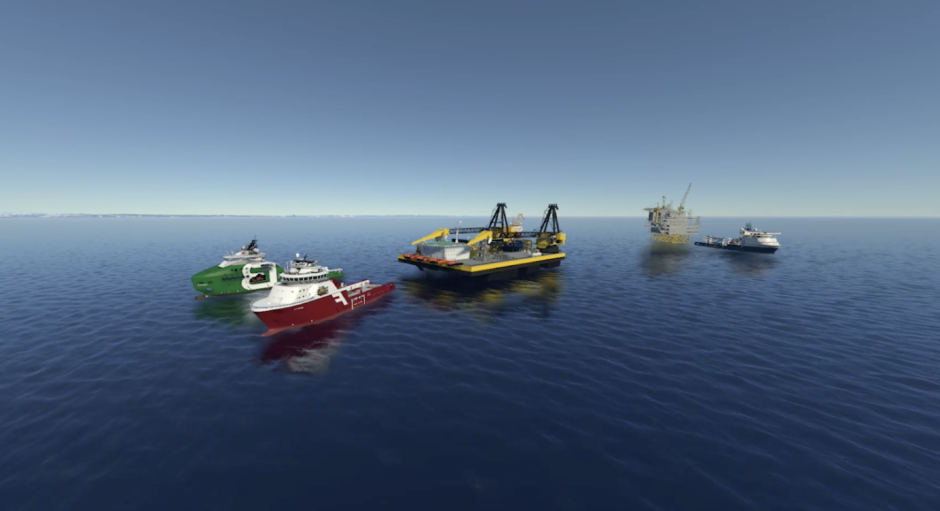

The simulator, which we liken to a giant gaming console, features a walk-in 300-degree visual immersive environment with four control stations and with the ability to split the screen into four different views, one for each station. These can be assigned control of any object or asset in the scene, for example a vessel, an ROV, a crane, or a new underwater lifting system. The highly detailed simulation is based on real-time physics calculations and can be modified live. This could be used to alter a crane specification to assess the effects on the operation.

To ensure realism of the simulations, the system allows the environmental conditions, including wave direction, height and period, current speed and direction, wind speed, direction and gusting etc. to be specified and changed. Vessels and similar assets within the simulation will then respond to these conditions as they would in real life. If the visibility is an essential aspect of the operation, the position of the sun can be specified and reduction of surface visibility due to fog, cloud or precipitation can be introduced. For underwater operations water turbidity can also be altered.

The simulator will allow companies working with the NDC to assess the viability and operability of new technologies before investment in physical prototyping. This route will offer cost savings for the sector and improved safety by anticipating scenarios and mitigating any problems in advance in a safe environment before actual deployment.

The system is complementary to physical scale trials and we are in discussion with an institution on how we use these two techniques together. The simulator allows the data to be implemented up to real size and a wide variety of environmental conditions trialled while the scale trials can provide valuable information to calibrate the model.

The NDC simulator is unique from existing facilities. Other simulators around the UK allow the training of drilling engineers, crane operators or vessel pilots and captains for port navigation. However, the NDC simulator provides an environment in which multiple entities (vessels, cranes, ROVs etc.) can be controlled and interact on a single task.

Hosted at the National Decommissioning Centre, the opportunities for the simulator are not tied to oil and gas decommissioning. There are many prospects around the technical aspects of offshore and floating wind installation and decommissioning and a massive opportunity around basin-wide decision making and energy integration using the simulator’s data overlay capability.

Professor Richard Neilson is director of NDC and Malcolm Stone is business development analyst, NDC

Contact Us

e: email enquiries@ukndc.com

t: +44 (0) 7776 596006 or +44 (0) 1224 274403

Twitter: @decomcentre

LinkedIn: linkedin.com/showcase/thendc