Pipeline technology specialist STATS Group has successfully completed the largest number of simultaneous pipeline isolation projects in its 23 year history.

During the 2021 summer shutdown season, STATS supported six separate Tecno Plug isolation deployments in the UK North Sea, on pipelines ranging from 20” to 36” in diameter. The projects were on critical pipeline systems on behalf of multiple clients, with the isolation periods ranging from 10 to 45 days.

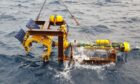

Isolation activities were carried out on and offshore at various locations and included the use of STATS’ remote monitoring system, which allowed Tecno Plug isolation tools to be monitored continuously via satellite from the firm’s remote monitoring centre in Kintore, Aberdeenshire.

The satellite monitoring technology enables customers to reduce site personnel on board requirements on their oil and gas installations during breaking of containment activities, whilst still ensuring that the isolation status is continually monitored.

The majority of Tecno Plugs deployed as part of the shutdown campaigns incorporated leak test modules, which allowed operators to perform reinstatement testing of new valves and pipework without disturbing the integrity of line isolations.

Each isolation scope was carried out with design, manufacturing, testing and project support being provided locally from STATS Group’s Kintore headquarters. Factory acceptance testing was also live-streamed remotely to clients, ensuring the client had full participation and oversight during the testing phase, despite the logistical restrictions necessitated by the Covid-19 pandemic.

The summer shutdown period saw a surge in demand for STATS’ process plant solutions which supported both North Sea and international clients with the provision of vapour barrier and localised weld testing services, with many requirements being delivered in quick turnaround times, due to the inevitability of unforeseen scopes that appear.

In addition, STATS worked closely with multiple North Sea operators in the manufacture and installation of its topside mechanical pipe connectors. These units were provided in sizes ranging from 2” to 20” as a safe and permanent cold-work solution, removing the associated risks of welding, and were installed on several key platform systems, including instrument air, diesel, and the larger of the units on flare systems.

STATS Group sales director Ron James said: “This has been our busiest period in terms of simultaneous isolation workscopes, but careful planning meant we were able to build and test in advance the necessary tools and equipment, so that everything was in place to be deployed during the optimum shutdown window.

“Our remote monitoring centre means we are able to reduce the number of personnel on board an installation during the length of the shutdown – thereby offering cost savings to our clients, while maintaining the highest level of safety monitoring.”

Recommended for you