The Future North Sea event sponsored by Schlumberger discussed the technologies needed to make the North Sea fit for purpose in a net zero world.

Mikki Corcoran, VP for sustainability at Schlumberger noted: “We realise as an industry we have a responsibility and an opportunity to help decarbonise oil and gas and we are on that task—but much work is needed”.

In December 2019, we were the first company in the upstream exploration and production (E&P) services sector to announce its commitment to setting a science-based target to reduce its GHG emissions, aligning us with the environmental goals of the Paris Agreement.

In June 2021 we announced our commitment to net zero by 2050. With minimal reliance on offsets, we are focused on reducing Scope 1, 2 and 3 emissions across the entire value chain aligned with a science-based carbon budget.

Transition Technologies

Our Transition Technologies portfolio is comprised of technologies and solutions that enable more sustainable operations while simultaneously driving efficiency, reliability, and performance.

To support the Transition Technologies portfolio, we have established a comprehensive framework that enables consistent impact quantification of the broad range of products and services offered by Schlumberger. Only those technologies that have passed through this process and meet internal thresholds for this quantified impact are qualified as Transition Technologies.

Our Transition Technologies support the UN Sustainable Development Goals and are mapped to quantifiable solution attributes that enable our customers to make more informed choices.

We have divided our Transition Technologies into five themes targeting sustainability challenges and opportunities across the E&P value chain:

- Planning and assessing operations to reduce or eliminate fugitive and vented methane emissions

- Minimising well construction CO2 footprint

- Optimising operations to reduce or eliminate flaring

- Full field development collaborations to drive sustainable solutions

- Electrification of infrastructure

Impact of Transition Technology

We are already delivering solutions using our transition technologies and helping our customers begin to make a difference in their carbon footprint.

One recent example is the installation of a OneSubsea® subsea multiphase boosting system – a solution that will reduce the cost and carbon impact of producing an additional 16 million barrels of oil in the North Sea. Leveraging an all-electric control system, the multiphase boosting system requires less than 50% of the energy to produce the same volume of oil as compared to gas lift, avoiding 200,000 tons of CO2 equivalent over 10 years of operation.

End-to-end emissions solutions for methane

Complementing our Transition Technologies portfolio, our newly launched Schlumberger end-to-end emissions solutions (SEES), offers a customisable end-to-end solution to help our customers in methane detection, monitoring and abatement and routine flaring monitoring and elimination.

To support this service, we have access to a uniquely wide range of technologies and our industry-leading domain knowledge allows us to identify the most effective plan and approach for decarbonising any operator’s assets.

Role of technology in reducing decommissioning costs

Schlumberger has a long history of the abandonment market and decommissioning in the North Sea. For example, a recent project showing the operational benefits of Simultaneous Operations (SIMOPS) during a platform decommissioning where our digital slickline enabled three wells to be entered, abandoned, and suspended concurrently. This not only delivered a considerable time saving for the client, but crucially was able to be carried out with no detriment to operational safety.

A key element to this project was our collaboration with the customer and our local partners, enabling lessons learned to be shared and ultimately helping reduce the cost of decommissioning for our customer. We had two digital slickline units to support the SIMOPS operations, moving away from conventional slickline memory deployment or e-line (wireline) deployment to execute plugging and abandonment (P&A).

Our digital slickline technology enabled streamlined execution by combining two services into one cable conveyance. Moving to this technology eliminated additional rig ups between conventional slickline and e-line (Wireline), thereby reducing equipment handling and increasing operational efficiency.

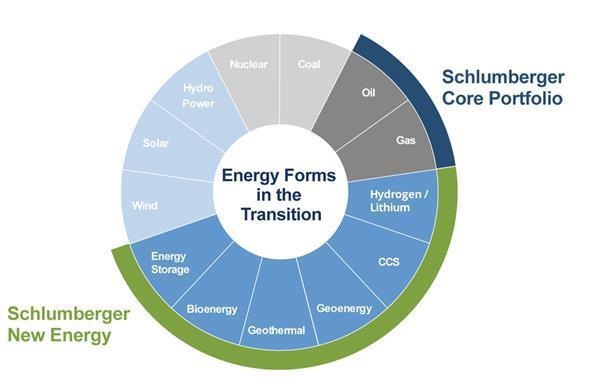

New energy ventures

The energy transition is a reality that’s accelerating in the North Sea. To drive this transition, Schlumberger continues to invest in new energy technology ventures and innovative partnerships in strategic sectors.

Today, our portfolio includes ventures in carbon capture and sequestration (CCS), geo-energy for heating and cooling of buildings, geothermal power, clean hydrogen, sustainable lithium production, and stationary energy storage sectors. In each of these sectors we leverage our expertise, technology deployment capabilities and global footprint, and collaborate in strategic partnerships to accelerate the low-carbon and non-carbon solutions to emerging new energy markets.

Collaboration

The future of our industry lies in collaboration—not just within our industry, where taking a new perspective on how we work together can speed decarbonisation of our operations – but in partnerships with other sectors that can accelerate the speed to innovations that will impact industries beyond ours.

In Schlumberger, we believe many of the key aspects of how our industry can, and must change, hinge on collaboration. Going forward, we must step up collaboration, which can only be fully achieved with a mindset of partnership and alignment throughout the entire value chain.

To make the impact we need by 2050, we must do this not just in oil and gas, but many other sectors where energy expertise can help decarbonise more quickly. Industries must share knowledge and work toward solutions together, combining domain expertise, which will accelerate innovation and create mutual value much faster than can be achieved in isolation.