Pioneering technology that “sucks” carbon dioxide out of the air could be up and running in Aberdeenshire around the middle of the decade.

Banchory-based Pale Blue Dot Energy (PBDE) is working with Canadian firm Carbon Engineering (CE) to develop the UK’s first commercial-scale direct air capture (DAC) plant.

They are considering building it close to PBD’s planned Acorn carbon capture and storage (CCS) facility at St Fergus gas terminal, near Peterhead.

If it goes ahead, the project could deliver huge environmental and economic advantages to Scotland and the UK.

A large-scale DAC plant would create around 1,500 jobs during construction and 100-200 for the operational phase, said Steve Oldham, CE’s chief executive.

It would also require the investment of hundreds of millions of pounds.

Full-scale DAC facilities can be built to capture one million tonnes of carbon dioxide per year each, equivalent to the annual emissions of 250,000 cars or the workload of 40m trees.

PBDE and CE have not decided which location would be best for the UK plant.

But PBDE managing director Alan James said the north-east was in “pole position” and

Mr Oldham added that picking the region would “make a lot of sense”.

It boasts ready access to North Sea reservoirs, with their huge storage potential, and a workforce who understand many of the processes involved in DAC.

In addition, the area is capable of hosting large renewable energy developments that could power the DAC plant, which would permanently store the carbon dioxide it captures below the seabed.

This would fit in well with PBDE’s Acorn project, which involves transporting carbon dioxide from St Fergus gas terminal, through the Goldeneye pipeline and into the depleted Goldeneye reservoir.

PBDE hopes Acorn will be operational by late 2024, while the first DAC project could be operational about two years later.

CO2 time travellers

Direct air capture (DAC) technology has been likened to “time travel” as it lets companies take responsibility for and scrub out past emissions.

Firms and industries who face huge challenges to reduce their emissions can enter into contracts with DAC plant operators, who will capture an agreed amount of carbon dioxide for the customer.

If businesses know how much carbon dioxide they emitted following their launch, they could pay to have that same volume removed from the atmosphere.

Doing so would effectively “reset” the company’s carbon footprint, taking it back to the day it was incorporated, said PBDE’s Alan James.

“For some, installing decarbonisation technology may simply never be commercially or logistically practical,” he said.

“DAC will provide a mechanism for those businesses to reduce their climate impact effectively and allow others to remove from the atmosphere the emissions that they were responsible for in the past.”

DAC works by pulling in atmospheric air then, through a series of chemical reactions, extracting the carbon dioxide from it while returning the rest of the air to the environment.

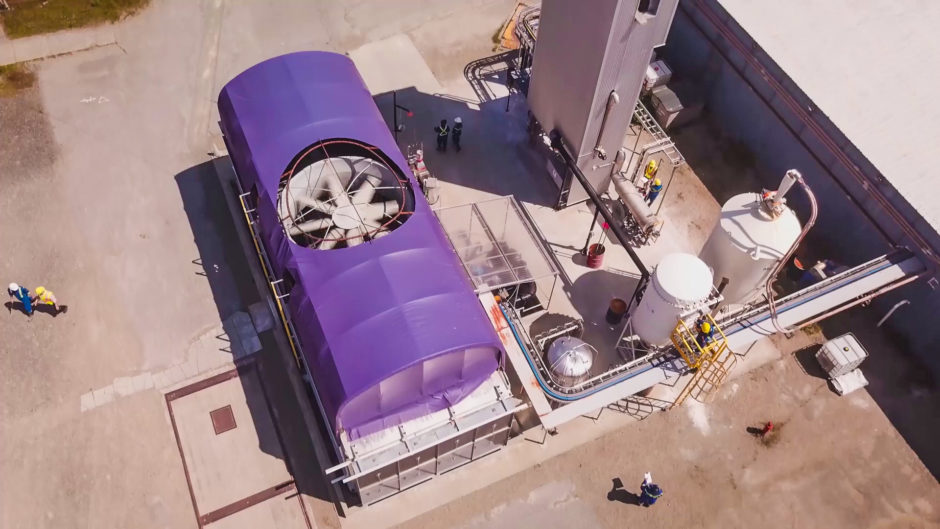

PBDE’s new partner CE, a privately-owned firm whose investors include Microsoft co-founder Bill Gates, has had a pilot facility in Squamish, British Columbia, since 2015.

It is currently engineering a commercial-scale plant in Texas alongside a subsidiary of oil firm Occidental.

Critics warn that DAC is expensive, energy intensive and a distraction from more conventional emissions-busting technologies.

However, the UK Government appears willing to back the technology, having recently pledged £100 million to support its development.

PBDE and CE intend to submit an application for funding in the coming months.

Recommended for you