The UK’s Energy Technologies Institute (ETI) has struck a deal with Blade Dynamics to develop and demonstrate the technologies for constructing what are billed to become the longest wind turbine blades ever built.

As part of the £15.5million project the ETI will become an equity investor in the Isle of Wight-based blade developer – helping with technology development and allowing the company to grow its workforce by up to a third in the short-to-medium term.

This is the second time in 12 months that the public-private funded organisation has provided private equity funding to a British SME developing innovative new technologies.

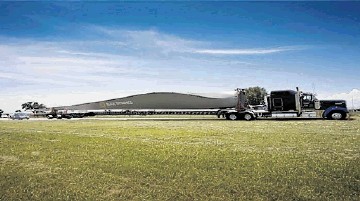

Blade Dynamics will construct blades of 80-100m in length, incorporating carbon fibre rather than conventional glass-reinforced plastics. This compares with blades now deployed offshore of 60-75m.

Carbon fibre has for some years been successfully used in the manufacture of high-tech masts for some of the world’s most sophisticated sailing yachts. It is also used in aircraft.

The ETI-commissioned and funded project will be delivered using Blade Dynamics’ innovative design and manufacturing processes that construct blades through the assembly of smaller, more accurate and easily manufactured component pieces, rather than from extremely large and expensive full-length mouldings.

Following the manufacture of prototype blades the plan is to go into production late next year.

According to the ETI, structural testing for the first blade is then expected to be carried out at a UK test facility. The design of the blades will see them weigh as much as 40% less than conventional grp blades, enabling significant weight and cost savings to be achieved throughout the rest of the turbine system.

The design will also help to reduce the cost of the energy produced.

The intended end use for the blade technology is on the next generation of large offshore wind turbines currently under development with a capacity of 8-10 megawatts. This compares with the 5-6MW capacity turbines currently deployed offshore.

The first stage of the project will focus on blade design in collaboration with a major turbine manufacturer (OEM).

The project will also test detailed design and manufacturing technologies, extending Blade Dynamics’ current experience from manufacturing 49m blades.

The second stage is intended to establish and demonstrate the proposed manufacturing processes on blades designed for a current 6MW turbine.

A design will also be developed for blades for future 8 to 10MW turbines. Final project stages are intended to test and verify the prototype blade performance against the predicted performance.

Paul Trinick, offshore wind project manager at the ETI said: “Offshore wind has the potential to be a much larger contributor to the UK energy system if today’s costs can be significantly reduced.

“Investing in this project to develop larger, more efficient blades is a key step for the whole industry in paving the way for more efficient turbines, which will in turn help bring the costs of generating electricity down.

“Along with improved system reliability, the impact of larger blades is a crucial factor in helping to bring down the costs of generating electricity offshore.

“Our investment strategy here is to provide financial support to allow the company to develop its technology further, to accelerate and expand the testing of this UK technology, and to identify the large-scale development opportunity of this design approach.”

David Cripps, senior technical manager at Blade Dynamics, said of the tie-up: “We have worked hard on the design of this blade technology for a number of years now.

“Financial backing from the ETI for this project allows deployment on ultra-large turbines far sooner than would otherwise have been possible and as a result of this project we will be hiring new engineers and technologists to make this possible.

“Our driver is to make the generation of electricity through offshore wind both more reliable and more economical. We believe longer, low-weight blades to be a key part of the solution, but for such blades to be most effective we need to design their construction differently.”

Recommended for you