From time to time the idea of using renewable energy to support late life production or reduce operating costs of fields from start-up of production has surfaced in the North Sea and at least two Southern Gas Basin platforms were fitted with small wind turbines… Amoco’s Davy and Bessemer structures.

That was in the mid-1990s.

Now, an ageing field in the Middle East is getting a production leg-up through the use of solar panels developed by an American company to help extend oil recovery (EOR).

With easy oil resources mostly heavily exploited and with global energy demand set to rise thanks to economic and population growth, companies such as BP, Chevron, Shell, Statoil and others are turning to a variety of EOR techniques, including solar EOR, a form of thermal EOR, to boost recovery of oil resources from maturing fields.

Globally, average recovery rates are around 35% though Statoil’s average, for example, is just over 50% and others like BP are setting more aggressive targets, notably in the North Sea, helped by healthy oil prices.

According to the International Energy Agency’s (IEA), even a 1% increase in the average recovery factor could add more than 80billion barrels, or 6% to global proven oil reserves.

To address the high capital costs associated with solar, Fremont, California-based Glass Point Solar Inc. created the Enclosed Trough solar field, in which curved aluminum mirrors – used in place of solar panels – and an aiming system and other vulnerable components are enclosed within a commercial glasshouse structure typically used in agriculture.

The Enclosed Trough solar field harnesses solar power production that boosts oil recovery while reducing the amount of natural gas consumed in the process and carbon dioxide emitted by up to 80%.

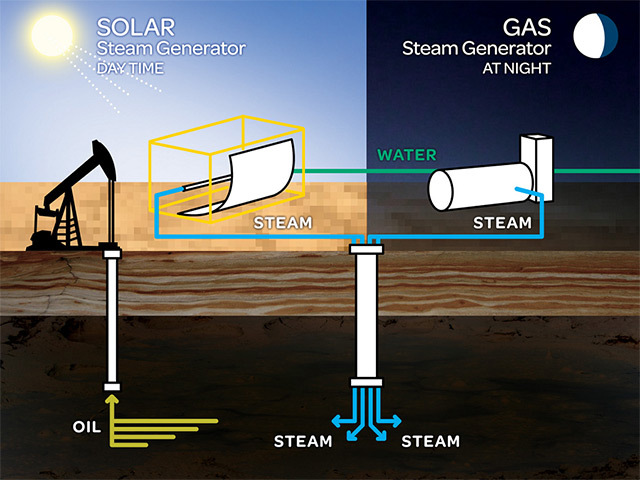

The mirrors track the sun during the day, focusing sunlight on a stationary boiler tube containing water. The sun’s heat then boils water in a stationary boiler tube that produces high pressure steam used to boost oil production.

The temperature of the steam is set by the requirements of the formation and low-cost distribution; power generation generally uses higher temperature superheated steam.

By using solar steam generators during the day and fuel-fired steam generators at night, the amount of gas burned to generate steam for EOR is reduced. Glass Point also reduced the high capital costs normally associated with solar fields by using a mass-produced glasshouse for low volume, custom designed solar components.

In February 2011, GlassPoint unveiled the world’s first commercial solar enhanced oil recovery (EOR) project at Berry Petroleum’s 21Z lease in Kern County, California. Built in less than six weeks, the system uses the sun’s radiant heat to produce approximately 1million BTUs (British thermal units) per hour of solar heat.

The enclosed trough preheats water to 190°F used as feedwater for Berry Petroleum’s gas-fired steam generators to enable more oil to be extracted from the more than 100-years-old field.

Petroleum Development Oman (PDO), the largest producer of oil and gas in Oman, partnered with GlassPoint to build the Middle East’s first solar EOR project. The pilot project was completed in less than one year, breaking ground in January last year and producing steam by December.

This 7MWth system is now in daily operation generating an average of 50 tons of emissions-free steam per day that feeds directly into existing thermal EOR operations at PDO’s Amal West oilfield.

The solar EOR facility passed its first performance acceptance test early this year, exceeding contracted steam output by over 10%. According to GlassPoint, this project serves as a performance and operational baseline for larger steam generators in Oman and is providing PDO with valuable information for planning potential larger-scale projects in the future.

Recommended for you