Ineos, a backer of the Acorn Carbon Capture and Storage (CCS) site in Aberdeenshire which missed out on UK Government funding last year, is now turning its attention to CO2 storage in Denmark.

However, the firm’s group communications manager, Richard Longden told Energy Voice on a trip to the Danish Greensand project, which is set to begin injection this week, that “the learning here will be applied to some of the other CCS projects that are being used.

“The similarity is that you’ve got the same you’ve got the infrastructure, you’ve got sort of skill sets out of Aberdeen that can all be utilised to drive that project forward, so it’s quite important.”

Ineos’ Grangemouth site which employs 1,300 people, aims to decarbonise via the Acorn development, and getting the CCS site up and running is integral to the longevity of that plant, as Mr Longden described.

“It’s important for the long-term future of that site, certainly. We need to make sure we’re able to reduce CO2, we’re committed to net zero by 2050 and we’ve got plans in place to achieve that and we’ve got an investment going in.

“It’s about maintaining the industry and the products that industry supplies as much as it is about maintaining the jobs in the oil and gas sector.

“It’s a win-win really if we can get projects like Acorn up and running and Greensand certainly is up and running, we see a very positive future for CCS.”

The Acorn project was up for government funding, however, the bid for the project was unsuccessful in the “track 1” process.

The CCS site, which is planned to operate out of Peterhead, is still up for the government cash in “track 2” of the CCS funding, that being said, there have been delays in the process that have cast doubts on when the Ineos-backed Co2 storage site would see the cash, even if it were successful.

What is Project Greensand?

It’s all well and good saying that INEOS will learn from Project Greensand, which is set to operate in the Danish North Sea, however, what is this offshore CCS site and how similar to the proposed Acorn is it?

Set to begin injection on the 8th of March, the CCS project in the Danish North Sea is a repurposed oil and gas well.

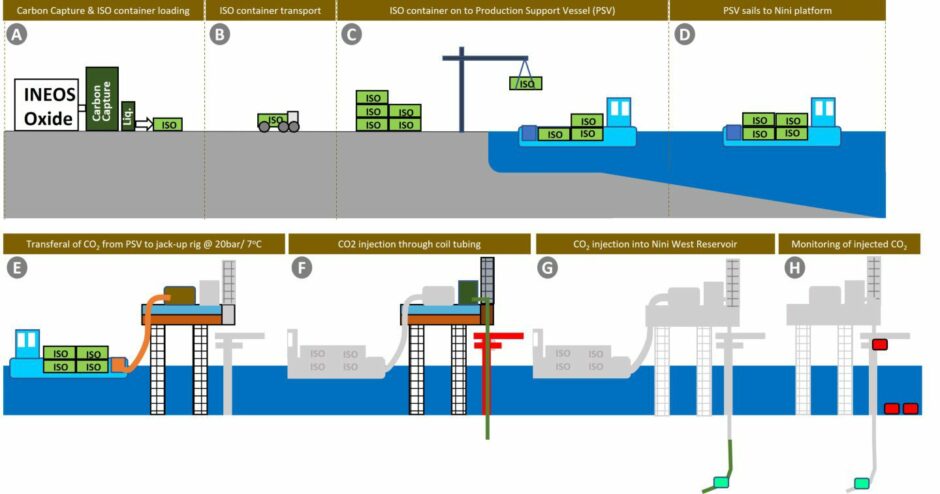

Unlike the proposed project in the north-east of Scotland, this Danish project aims to ship the carbon dioxide out to sea using tankers as opposed to Acorn’s pipeline solution.

Greensand is the most mature project of its kind in Denmark, the project has the potential to lock away between 0.45 to 1.45 million tonnes of carbon dioxide per year by the end of 2025/start of 2026.

The storage will take place in the INEOS-operated Siri area where there are currently a number of oil rigs.

The INEOS team in Denmark, along with the Danish authorities are confident about this project.

Mads Weng Gade, head of Denmark and chief commercial officer of INEOS Energy said: “The oil has been there for many, many years, so we’re quite comfortable around how it will stay down there, the CO2 as well.

“It’s been well sealed and recently the Danish geological institute published an article saying that they’ve investigated the underground and it seems like there’s a double ceiling, so it’s quite well protected in terms of having the Co2 down there.”

Testing the reservoir

According to Mr Gade, this first injection test is not in place to prove the technology involved works.

As he said: “So you’ve had capture for a while you’ve had ships sailing with CO2,” this test is partly to showcase how the supply chain can work together on a project like this.

The INEOS Denmark boss explained: “It’s about making sure that all of these value chain elements can go together, which hasn’t really been tested, so we can sail it out and we can inject it via the platform.”

The other reason for this initial test injection is more technical and will prove how accurate the previous geological surveys have been.

Mr Gade said while on the Siri platform: “The other part, which is important, is to see how the CO2 works in the reservoir when we inject it.

“Can we inject it at a certain pressure? Can we get the CO2 down there? Will there be issues with the sandstone?

“We’ve done all of the lab tests, we’re quite comfortable around it and we think it’s positive results, everything we’re seeing. But then again, it’s a different thing when you start doing it in practical and real life and you suddenly start injecting bigger amounts of CO2 into the reservoir.”

However, despite these concerns, the team on the Siri site are familiar with the geology of the area, having built up years of experience with the well in question.

“The good thing about our reservoir is we’ve been injecting water and we’ve also been producing for many years so we know what the reservoir can handle.

“So, we are well keeping ourselves well within the boundaries of what we believe is healthy and good for the reservoir.”

Having this experience with the local geology is one of the “clear advantages of going with a depleted oil field” the INEOS boss said.

“We’ve been producing here for more than 20 years so we know exactly how the hydrocarbons have been moving and we have really good geological oversight.

“That helps in terms of informing how much we think can be kept down there.”

Life on a CCS project

Moving from extracting hydrocarbons to injecting carbon dioxide into a well may seem like a big jump for the staff on board the Siri platform, however, the day-to-day of workers is not changing as much as you may expect.

Peter Bjerre, the maintenance supervisor for the Siri, spoke with Energy Voice during a trip to the greensand project and he said: “We’re still going to have an installation to maintain and to repair. We still have a lot of the same type of equipment.

“Obviously, there will be some changes with the installation with regards to injecting CO2 but the way we operate safety, mine and everyone else’s, will still need to be managed and maintained as well.

“So from our point of view, it will be much the same actually.”

On the Siri platform “everything starts with safety” according to Mr Bjerre, and this is something that will not change moving forward.

The way Mr Bjerre sees this transition, repurposing end-of-life oil and gas assets as CCS sites is a way to extend the lifecycle of a platform and increase its value for both the workers and the owners/ operators.

He said: “Like any installation producing oil and gas, there is a lifetime when the reservoirs are empty and you can’t produce more that’s in the reservoir.

“So you can use the installation for something else, as a satellite or whatever but looking at CO2, it’s essentially a new industry that uses the same facilities, the same installations and the same know-how.

“We’re very happy with this opportunity and this development while also being a part of the solution.”

The team on the platform look forward to moving away from oil and gas extraction and takes pride in the fact that they are moving towards greener employment.

The Siri maintenance supervisor explained: “We want to be part of the solution and we like to be offshore in the way we work here, how we work on an installation for two weeks and then we go home for three weeks.

“With the green energy and through the CO2 injection that will extend the lifetime of this installation and the facilities out here for the people working out here.

“Hopefully it will bring in new young that can see this as a future that we can benefit from and it’s very interesting if you like going offshore and you like this sort of work, it’s fantastic with a special work-life balance.”

Recommended for you

© Ryan Duff/DCT Media

© Ryan Duff/DCT Media © Supplied by INEOS

© Supplied by INEOS © Supplied by INEOS

© Supplied by INEOS © Supplied by Richard Longden

© Supplied by Richard Longden © Supplied by Richard Longden

© Supplied by Richard Longden © Supplied by Richard Longden

© Supplied by Richard Longden © Ryan Duff/DCT Media

© Ryan Duff/DCT Media