Spirit Energy has concrete plans for enabling a new zero energy system.

Following the sale of oil producing fields in the Norwegian North Sea in 2022, the firm, which is majority owned by Centrica (LON: CNA) has become almost entirely focused on gas production. And now it is looking to how to use its experience in this area to the next stage of the energy transition to store carbon.

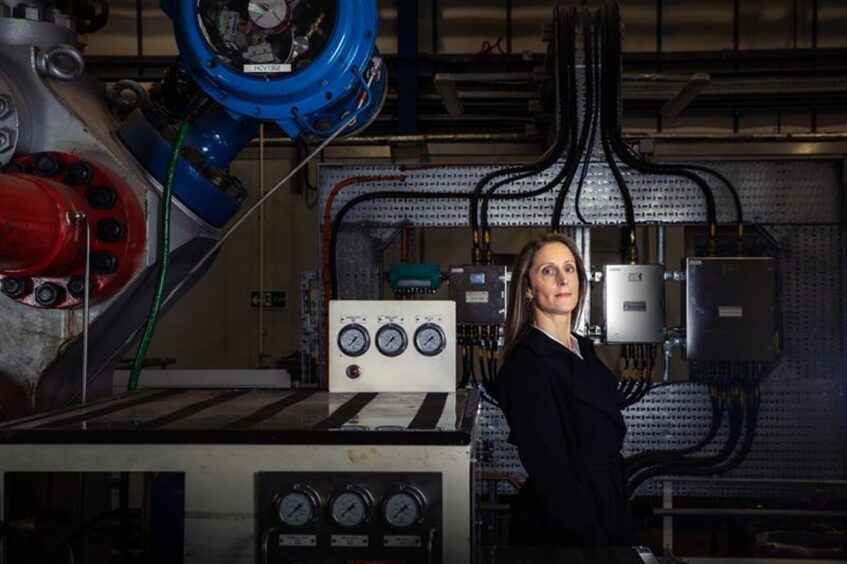

Susan Mackenzie is leading Spirit’s ambitious plans to repurpose depleted gas fields to create the UK’s largest permanent carbon store, capable of storing one billion tons of CO2.

Mackenzie moved to Aberdeen in 1999 to complete her MsC in environmental sciences. Her career started in the oil and gas industry which she admits she felt “conflicted” following her training.

“But you can work that conflict out because you need power, then you can try and get new developments to mitigate impact on the environment.”

Then the opportunity came with Spirit Energy to lead the Morecambe Net Zero (MNZ) project, which she did not hesitate to take.

“It was really easy,” she recalls when asked if she wanted to join the team.

Spirit Energy’s Morecambe hub has been producing gas for 40 years.

The firm estimates it could meet up to a quarter of the UK’s carbon storage capacity needs from 2030.

MNZ is not currently part of the UK’s carbon capture and storage (CCS) track system. Last year the UK government allocated £22 billion in support for two CCS projects, one of which is nearby to MNZ on Merseyside.

Mackenzie envisages going beyond current government allocations.

“We need to do it. And we need to find a route to it for not just two, not just four, but many projects,” she said.

“MNZ is probably the best project because of the size of a reservoir, and it is a proven container because it has held gas for the last 40 years.”

The size of the reservoir and its resulting capacity gives the project economies of scale which serves to reduce the levelized cost of abatement, a key metric used to measure the cost effectiveness of carbon reduction.

Spirit estimates the project is set to generate the equivalent of £1.8bn GVA by 2050, creating and safeguarding more than 13,000 jobs across Derbyshire, Staffordshire and Cumbria, which is closest the project.

Cementing relationships

Another unique aspect of the project is a partnership with some of the UK’s largest cement and lime producers. Cement production is considered to be one of the hardest industrial processes to reduce emissions, making capturing and storing its carbon output essential.

The Peak cluster includes Tarmac (LON: CRH), Breedon (LON: BREE), Belgium’s Lhoist and Aggregate Industries (SW: HOLN). These will provide the first customers of the MNZ project, with others due to come on board after 2030.

For Mackenzie it is a question of deploying the firm’s skills.

“What we are doing is trying to have a managed transition from gas production to carbon storage,” she said.

“There is some element of reusing existing facilties but the larger part is using our skill set – it is the knowledge and skills to redevelop those gras reservoirs into carbon stores.”

Before settling into her current role, she also did a two-year stint as a teacher with Voluntary Services Overseas (VSO) in Ghana. The experience delivered home to her how connected communities are to the environment.

“That was really important because you can see just different ways of life and the impact of the climate.

“If the crops don’t grow, for us we have to pay an extra 10p on a loaf of bread. It matters, climate change really does matter.”