It’s clear that hydrogen produced from renewable energy will play an important role in supporting our transition away from fossil fuels to a low carbon energy system.

But the precise nature of that role is more contentious. It is not obvious to everyone, for example, that the ‘hydrogen-ready’ domestic boilers we’re being promised will ever have these capabilities tested (much like my ‘Ferrari-ready’ driveway).

Electrification will often be the best route to decarbonisation – for example cars and domestic heat. But there are some applications – high grade industrial heat, large scale transportation and long duration energy storage among them – where electrification will be more challenging.

It is here that hydrogen will step in, providing a low carbon option where there are few alternatives. It is likely that these new use cases will drive the growth in global hydrogen demand, projected by the International Energy Authority (IEA) to double to 180 Megatonnes (Mt) by 2030.

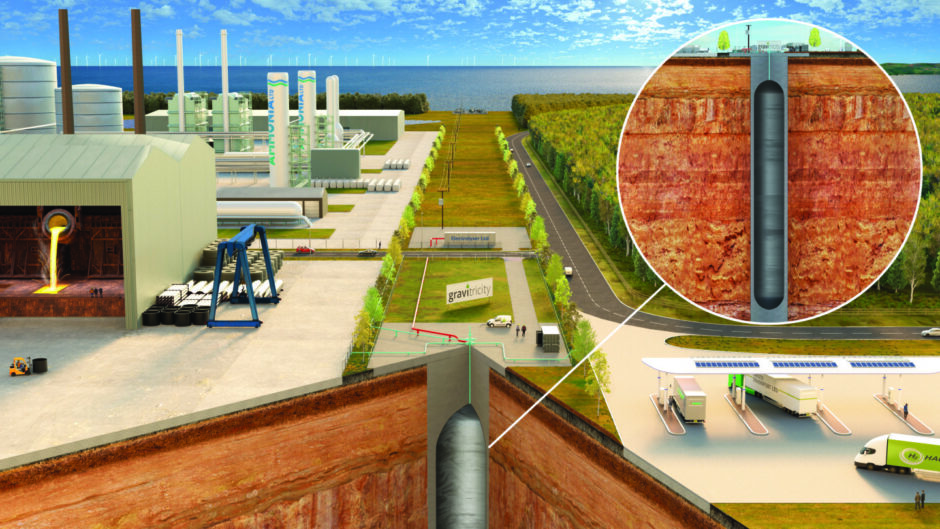

If this is right, then it is likely that green hydrogen will be produced, stored and consumed close to large, industrial sites with one or more significant users, often around the coast where cheap offshore wind generation can power the hydrogen electrolysers and compressors.

The ability to store hydrogen at these sites will be critical to ensure users have reliable flows when needed.

So which hydrogen storage solutions are most suitable for the requirements of these industrial sites? Two alternatives are commonly proposed:

- First, salt caverns. These are very large underground spaces created by injecting water to dissolve geological rock salt. The storage potential of each cavern is large, but they can only be situated where suitable salt formations exist. In the UK for example, only areas within Cheshire and East Yorkshire are known to have these formations, so Southeast England, as well as existing industrial clusters in South Wales and Scotland would be many miles from their nearest storage facility.

- At the other end of the scale are pressurised metal vessels. Unlike the caverns these vessels can be located anywhere. But hydrogen storage potential per cylinder is much smaller, and with all the metal required to contain the pressurised hydrogen, they are an expensive option which will take up valuable space on site while presenting a potential health and safety hazard to nearby (and not so nearby) infrastructure.

Both these approaches have significant shortcomings, and don’t offer the mid-scale storage solution most likely to be appropriate for the industrial hydrogen hubs of the future.

At Gravitricity, we have developed significant expertise in storing energy underground, and believe that purpose-built, underground hydrogen stores could be a ‘Goldilocks’ solution for industrial sites – big enough to deliver the likely needs of industrial hydrogen hubs. Our solution, which we call H2 FlexiStore, is based on a gas tight metal liner within an underground shaft, where the surrounding geology will allow us to store hydrogen at pressure safely and at a lower cost.

A single store, six metres in diameter and 365 metres deep, would hold up to 100 tonnes of pressurised green hydrogen – sufficient to refuel 1000 HGVS, or to power 500 buses for a week.

Crucially, the 100-tonne shaft capacity offers a mid-scale option specifically calibrated to deliver the likely needs of future industrial hydrogen hubs. And if rolled out nationwide, we calculate that just 1000 FlexiStores would meet a quarter of the UK Government’s predicted 2050 hydrogen storage needs.

It is not yet clear how the UK’s hydrogen economy will evolve – but in my view mid-scale hydrogen storage, close to where it is required, will be key.

Recommended for you