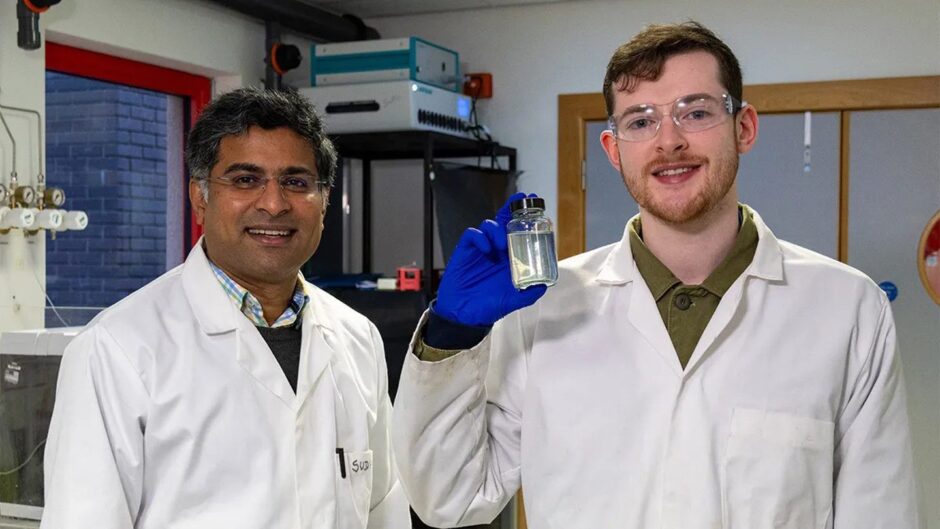

Scottish researchers have developed a method which could allow wastewater produced from the distilling industry to be used to create green hydrogen.

Scientists from Heriot-Watt University in Edinburgh have created a treatment process which could allow distillery wastewater to replace fresh water used to create the sustainable fuel.

Heriot-Watt University said distilleries in Scotland alone produce an estimated 1 million litres a year of wastewater from the whisky distilling process.

Globally, the distilling industry produces around 1 billion litres of wastewater.

The researches hope their method can divert this process into green hydrogen production, a process which currently consumes 20.5 billion litres of fresh water a year.

Heriot-Watt School of Engineering and Physical Sciences materials scientist Dr Sudhagar Pitchaimuthu said it takes 9kg of water to produce 1kg of green hydrogen.

“Meanwhile, every 1 litre of malt whisky production creates about 10 litres of residue,” he said.

“To help protect the planet, we need to reduce our use of fresh water and other natural resources.

“So our research focused on how to use this distillery wastewater for green hydrogen production with a simple process that removes waste materials present in the water.”

Nanoparticle method

In collaboration with the University of Bath and The Scotch Whisky Research Institute, Dr Pitchaimuthu and his team developed a nanoscale material, called a nickel selenide, to allow distillery wastewater to replace fresh water in the green hydrogen production process.

The nanoparticle – approximately one in 10,000th the diameter of a human hair – treats the wastewater so it can be used in an electrolyser, which uses electricity to split water into hydrogen and oxygen in a process known as electrolysis.

When the electricity used in the process is produced from renewable electricity, the resulting product is known as ‘green hydrogen’.

Unlike fossil fuels, hydrogen does not emit carbon when burned.

Because of this, increasing green hydrogen production is considered a crucial component of efforts to achieve net zero.

Dr Pitchaimuthu said electrolysers usually only work with fresh water and typically fail because of the substances in wastewater.

However, the process developed through the team’s research produced similar or slightly higher quantities of green hydrogen from the wastewater compared to the results from fresh water.

Wastewater hydrogen has “huge” potential

Dr Pitchaimuthu said the wastewater treatment process has “huge” potential.

“Using industry wastewater means we can reduce the extensive freshwater footprint associated with green hydrogen production,” he said.

“Our research also shows how we can use the world’s resources more sustainably to produce clean energy.”

Heriot-Watt University said the next steps for the research team include developing their own electrolyser prototype and scaling up production of their nickel selenide nanoparticles.

The team will also be analysing the distillery wastewater to discover whether other materials of value could be salvaged from it, alongside hydrogen and oxygen.

Whisky industry’s green hydrogen dreams

The Scottish whisky industry has invested in several green hydrogen projects in recent years as part of efforts to decarbonise.

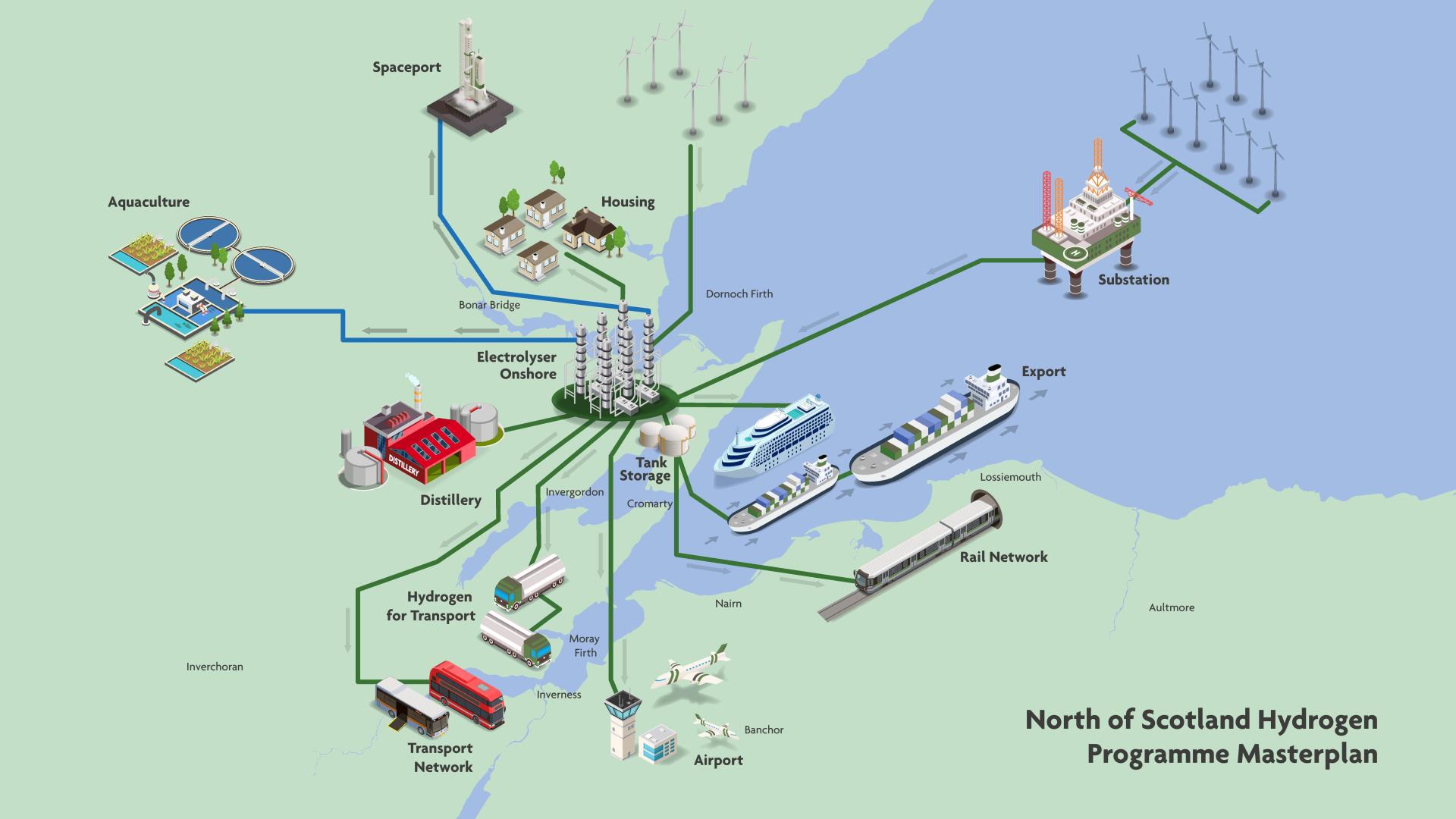

ScottishPower and Storegga, the firm behind the Acorn carbon capture project, announced a green hydrogen partnership to “transform” industry in the Highlands in 2022.

The Cromarty Hydrogen Project follows a feasibility study between ScottishPower and Storegga in collaboration with distillers Diageo, Glenmorangie and Whyte & Mackay, all of which have operations in the Cromarty region, to take Scotland’s national drink greener.

In 2021 Aberdeenshire distiller Ardmore announced plans for a £3.6 million “WhiskHy” project to install an electrolyser at its facilities in Kennethmont.

Meanwhile, InchDairnie Distillery in Glenrothes recently received £600,000 in funding from the UK government to install a boiler powered by hydrogen.

Recommended for you

© Supplied by Shutterstock

© Supplied by Shutterstock © Supplied by SSE

© Supplied by SSE © Shutterstock / JoffreyM

© Shutterstock / JoffreyM © Supplied by Storegga/Scottish Po

© Supplied by Storegga/Scottish Po