WE REGULARLY report on joint industry projects (JIPs) launched through the North Sea’s Industry Technology Facilitator, ITF, but what happens to those technologies once the initial project is completed?

Here we check up on some of the 180 projects that ITF has kicked-off.

One of the first companies that ITF helped was the geophysical service firm ARKeX, which has been at the forefront of developing the next generation of gravity gradiometry for commercial exploration.

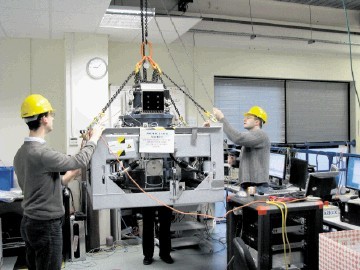

ITF facilitated a JIP relating to development of ARKeX’s Exploration Gravity Gradiometer (EGG), which uses minute variations in the earth’s gravitational field to locate subsurface oil, gas and mineral bearing structures from a plane flying overhead.

Following this JIP, venture capital funds were secured, the development of EGG continued, and ARKeX says it is now accelerating towards deployment. Some flight trials have taken place and it is anticipated that a more intensive series of airborne tests will start soon.

Prof Steve Taylor of Liverpool University first approached ITF with a proposal for a study to assess oil and gas industry applications for his miniature mass spectrometer. This led to a project that investigated the potential for an oil-in-water monitoring system using membrane inlet mass spectrometry (MIMS).

When Energy last reported on the project three years ago, field trials were about to start at the Flotta oil terminal in Orkney.

Commenting on the trials, Prof Taylor said: “Two types of North Sea crude were assessed and confirmed the quadrupole mass spectrometer-based system has the potential to complement exist ing oil-in-water monitors by detecting different oil types and specific hydrocarbon concentrations, such as aromatics, with high accuracy.”

Advanced Sensors Ltd has now built a prototype combined oil-in-water monitor with on board mass spectrometer (ATOM).

Cost and risk generally increase as R&D progresses, so technology development in this industry can be a lengthy and expensive process; however, an increasing number of technologies with which ITF has been involved are now seeing commercial application.

ITF’s technology manager Keith Mackie told Energy: “Our funding allowed CTES, now part of National Oilwell Varco, to begin the development of its Slickline Fatigue software and hardware product.

“The ITF facilitated phase was followed by several years of CTES-funded development which included adaption and expansion of the software model’s scope and development of a field data acquisition system. An element for corrosion was also added to form a rounded picture of how slickline degrades over time.”

Another now market-available technology that secured support via ITF is the Mud Watcher.

Mud Automatics approached the facilitator seeking field trial support for the device, which the firm was confident offered a vastly improved alternative to the batch testing process used to monitor mud weight and viscosity since the 1950s.

The company has since secured sales and rentals in the North Sea, US, Mexico, Greenland and Australia, and plans to trial its complementary Rheo Watcher, which monitors the mud’s rheological characteristics (PV & YP) continuously and in real time, during 2012.

Seabox (formerly Well Processing) developed its SWIT system to provide subsea seawater treatment for water-flooding of hydrocarbon reservoirs.

Improving recovery is important in our maturing industry and Seabox says SWIT increases IOR potential by achieving total flexibility in reservoir drainage strategies, enabling injection of as much treated seawater as required, where and when required, without host platform restrictions.

Mackie: “Since Energy reported on SWIT in 2009 it has undergone 15 months of full-scale subsea trials with excellent plant reliability and water quality results. Recent work on detailed design and interfaces means SWIT is ‘ready to go’ and being considered by several operators for field applications.”

Seabox is kicking off a new project this month to test whether SWIT quality water can increase the lifetime of membranes used for production of low sulphate and salinity water, beneficial for IOR/EOR.

If successful, this could be a significant step towards membrane treatment on the seabed.

Summing up, Mackie said: “Taking technology from concept through to commercial deployment is a costly, time consuming and complex process, but I believe that by facilitating dialogue and collaboration among technology developers and end users, ITF can play a significant role in ensuring that innovative new technologies get the support they require to meet the industry’s needs”.

ITF will be holding a series of Technology Challenge Workshops and issuing new calls for proposals during 2012. Topics include: unconventional reservoir characterisation; heavy oil; subsea; downhole pressure and temperature monitoring; unconventional tight gas productivity stimulation and a number of other priority areas.

For further information visit www.oil-itf.com